Computer Equipment

The essence of computer equipment is the highly integrated application of electronic components. Its performance improvement directly depends on the progress of semiconductor technology, packaging technology, and the coordinated optimization of passive components and active devices.

1. What are the Core Components of Computer Equipment?

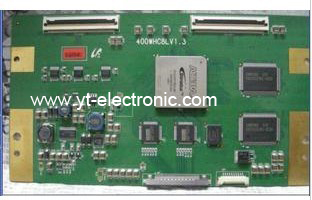

Integrated Circuit (IC)

As the "brain" of computer equipment, integrated circuits integrate transistors, resistors, capacitors and other components on semiconductor wafers through microelectronics technology to achieve functions such as logic operations and data storage.

Semiconductor Devices

They include CPU (central processing unit), GPU (graphics processing unit), memory chips (such as DRAM, NAND flash memory), etc. These devices are based on silicon-based semiconductor materials and realize signal processing and information storage by controlling current.

Passive Components

Such as resistors, capacitors, inductors, etc. are used for current limiting, filtering, voltage stabilization and other functions in the circuit to ensure the stability of computer equipment operation.

2. Typical Equipment and Functions

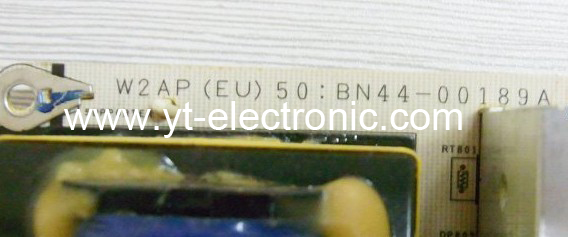

Computer host

It consists of a motherboard, power module, storage device (hard disk/solid-state drive), etc., and relies on integrated circuits and semiconductor devices to complete data processing, storage and transmission.

Peripherals and interface modules

Such as display driver circuits, USB interface controllers, network communication modules, etc., involve the coordinated work of discrete devices such as field effect transistors (FETs) and thyristors.

Industrial control equipment

Including CNC systems, automated robots, etc., which require high-precision sensors, and power semiconductors (such as IGBTs), etc. to implement complex control logic.

3. Production and Manufacturing Technology of Computer Equipment

The production of computer equipment depends on special equipment for the electronics industry, such as:

Integrated circuit manufacturing equipment: lithography machines, etching machines, ion implanters, etc.

Assembly and testing equipment: surface mount machines (SMT), automatic welding robots, functional testers, etc.