Circuit Protection

1. What are the Core functions of Circuit Protection?

Circuit protection is a protection mechanism for electronic devices or systems against abnormal electrical conditions, mainly including the following functions:

Overvoltage protection: Prevent device breakdown caused by voltage transients (such as surges, and electrostatic discharge). Common protection components include varistors (MOVs) and transient suppressor diodes (TVSs).

Overcurrent protection: Prevent thermal damage to the circuit caused by current overload by fusing or current limiting. Typical devices include self-resettable fuses (PPTCs) and traditional fuses.

Temperature protection: Cut off the circuit by fusing or temperature-sensitive switches to prevent overheating, such as low-temperature alloy over-temperature protection components.

Compound protection: Integrated temperature, current, and voltage multi-monitoring protection solutions (such as TFR), widely used in high-safety demand scenarios such as lithium batteries.

2. What are the Main components and principles of Circuit Protection?

MOV (metal oxide varistor)

Absorbs transient overvoltage energy through nonlinear resistance characteristics, suitable for power line surge protection.

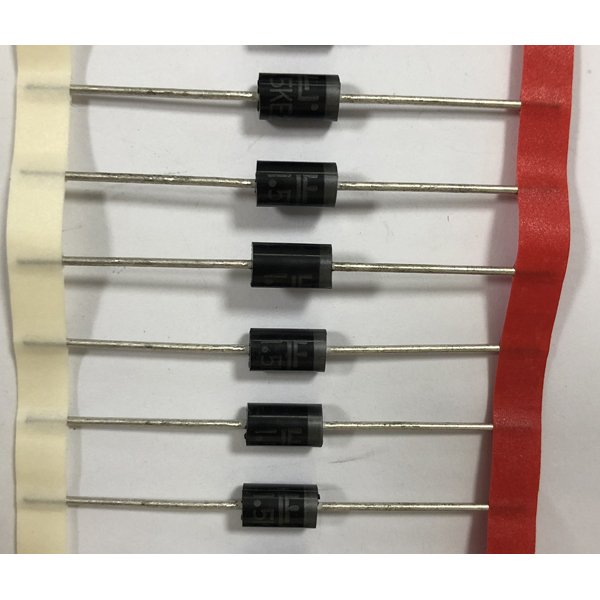

TVS (Transient Suppression Diode)

Quick response (nanosecond level) voltage spikes, used for ESD protection of precision circuits.

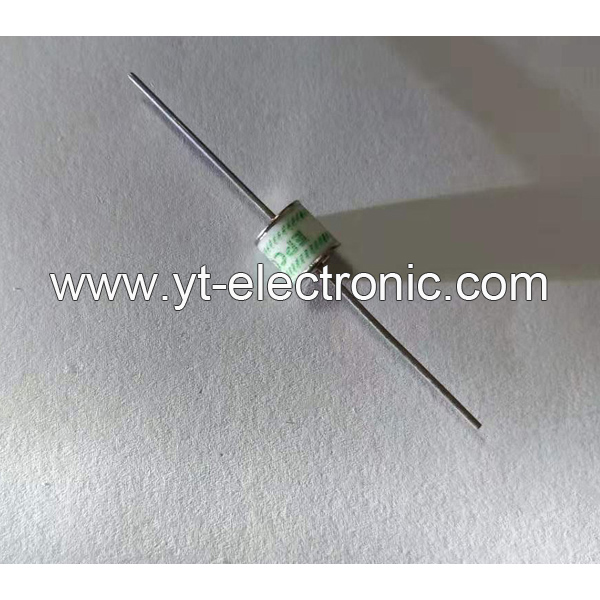

GDT (Gas Discharge Tube)

Uses the principle of gas ionization to discharge high-energy surges, with a current resistance of 20kA, suitable for lightning protection of communication equipment.

PPTC (Self-Resettable Fuse)

Overcurrent protection is achieved based on temperature-resistance characteristics, and can automatically recover after the fault is removed.

TFR (Overtemperature and Overcurrent Protection Device)

Simultaneously monitors temperature and current anomalies, and is suitable for complex scenarios such as motors and 3C products.

3. Where is Circuit Protection Used?

Consumer Electronics: High-speed transmission devices such as smartphones and USB interfaces rely on TVS/MOV to prevent static electricity and surge shocks.

Automotive Electronics: The on-board power system needs to deal with the startup peak voltage, and MOV and polymer capacitors work together to ensure stability.

Industrial Equipment: The power system uses a combination of GDT and MOV to resist lightning strikes and grid fluctuations.

Communication base station: Ceramic gas discharge tubes (GDT) and semiconductor discharge tubes are preferred in lightning protection design.

4. Technology development trend of Circuit Protection

High integration: A single component integrates multiple protection functions (such as TFR) to simplify the complexity of circuit design.

Intelligent response: Combine sensors and microcontrollers to achieve dynamic threshold adjustment and improve protection accuracy.

High-temperature material innovation: Develop high-temperature resistant alloys and polymer materials to expand the scope of application in extreme environments.