What Are the Materials Required for SMT Mounting?

This article introduces the solder required for SMT patching, the advantages and disadvantages of these solder materials, and their applicable scenarios.

Table of Content

Materials required for SMT mounting include solder, adhesives,fluxes, solder pastes, fluxes, cleaning

agents, heat conversion media, etc.

Soldiers are a key structural component in SMT assembly. The solder joint is formed by connecting the

metal surfaces of welding objects.

Solders are used for different purposes and according to the process requirements. Common solders used

in SMT mounting include lead-free solder , tin/lead solder , and tin/silver solder.

Tin and lead solder are used in the traditional SMT process. This solder has a low melting point and is

easy to use.

Tin-lead has been phased out because it contains lead. It is now being replaced with safer, more

environmentally friendly, lead-free solder. Tin-silver is a non-lead solder that consists primarily of

tin and silver with a little copper.

This solder has a low melting point and is characterized by high reliability, high weld strength, and

good fluidity. Tin-silver has therefore become the standard in SMT patches.

Lead free solder has a lower environmental impact. Tin, nickel, niobium, and silver are

its main components. Lead-free solder has many advantages over tin-lead, including the fact that it is

environmentally friendly, does not contain any lead, and offers high-quality welding.

The melting point of the lead-free solder, however, is higher. Soldering requires a higher temperature,

and a longer time. This makes it more difficult.

The choice of solder has a major impact on the quality of soldering and efficiency of SMT processing.

To ensure weld quality and reliability, it is important to consider the specific requirements of the

welding process and the environment in which we will be using solder.

Flux is a factor that affects the quality of SMT processing patch welding.

Flux is used to clean the metal surface before welding. Fluxes used in SMT processing include rosin and

organic solvents.

Rosin, a traditional flux for soldering. Rosin and fatty acids are the main components.

This soldering flux is low-cost and easy to use, but is also volatile and flammable. We need to be

careful when using it.

The organic solvant is an innovative flux. Alcohols, ketones and ethers are the main

components. This type of flux is non-flammable and volatile. It can also remove oil stains, oxides, and

improve the welding quality.

The disadvantage of organic solvents, however, is that they can be volatile and must be disposed of

quickly.

Hydrogen Peroxide is a safe and environmentally friendly flux, whose primary components

are hydrochloric acids and hydrogen peroxide.

This flux has the advantage that it does not contain heavy metals, and also meets the environmental

protection standards. It can also remove oil and oxide stains, improving the quality of welding.

Hydrogen peroxide has a high corrosive property. When using it, we need to be careful.

In summary, the choice of flux for SMT processing is critical to its efficiency and soldering quality.

It is important to select flux according to the welding process and the surrounding environment in order

to achieve the best possible quality and reliability. To protect both the environment and your safety,

you should also pay attention to how to safely use and dispose of flux.

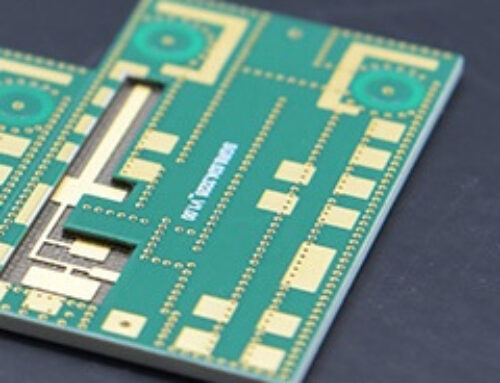

In SMT processing, the adhesive is used to bond the patches. The adhesive is used

primarily to mount electronic components onto PCB board.

Type and properties of adhesives will also influence the mounting effect. These include viscosity

(liquid), curing time (hardness), etc. The quality and efficiency of mounting can be improved by

choosing the right adhesive.

Common adhesives used in SMT include polyurethane and acrylic acid.

Epoxy Resin has a high viscosity and is used as an adhesive. It also has a high degree

of hardness and resistance to high temperatures. The disadvantage of epoxy is that it’s highly

toxic. Use it with caution.

Polyurethane has the advantage of being an environmentally-friendly adhesive. It is

non-toxic and odorless. It also has a low viscosity. The disadvantage of polyurethane, however, is that

it cures slowly and requires a lot of time before you can move on to the next stage.

Acrylic acid, a new adhesive type. It has low viscosity and moderate hardness. It is

also easy to evaporate, leaving no residue. Acrylic acid has the disadvantage that it is volatile and

needs ventilation.

When choosing adhesives it is important to consider the mounting quality and

reliability. To protect the environment, and your personal safety, you should also pay attention to how

adhesives are used and disposed.

Flux, cleaning agents and heat conversion media are also required for SMT patch

processing.

Flux Cleanse and activate the metal surfaces for the next welding step.

Cleaning Agents are used for cleaning pollutants and waste produced during SMT patch

processing.

Heat Transfer Media is mainly used for heating and cooling equipment and materials in

SMT patch processing.

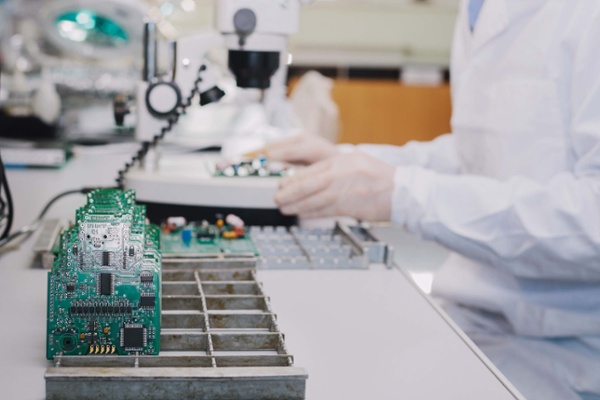

SMT patch processing is a complex process that requires a variety of materials and processes to achieve

the highest welding efficiency and quality.

The mounting effect of the product can be improved by selecting appropriate materials and processing

materials. It is a strong support in the production of electronic products.

related Posts

Contact us

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Teams: alek_youte

Email: sales@yt-electronic.com