SMT Production Line Overview

This article mainly introduces the composition equipment, process flow, characteristics, and future development trends of SMT production line.

Table of Content

- Y&T Technology Development Co.,LtdProfessional distributor of electronic components

- What Is a SMT Production Line?

- Composition of SMT Production Line

- SMT Assembly Line Ways

- SMT Production Line Process

- SMT Production Line Characteristics

- Use of SMT Production Lines

- Trends in Development of SMT Production Line

What Is a SMT Production Line?

The Surface Mount Technology Line refers to surface assembly equipment, including Surface Applying

Equipment, place-and-place machines, welding machines and cleaning machines.

Composition of SMT Production Line

Components of SMT production lines include mainly the following categories.

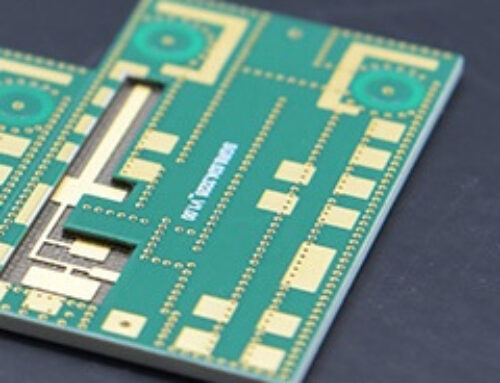

1) Solder Paste Printing Machine

The purpose of this tool is to apply solder paste, patchtape or a combination on the pads of PCB.

2) Dispensing Machine

Its main purpose is to fix components onto the PCB.

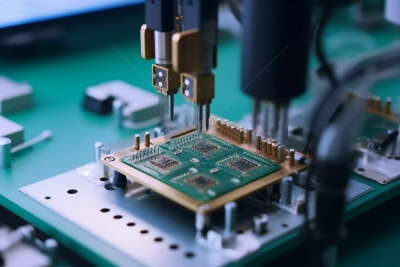

3) SMT Machine

Surface-mount components are accurately installed to the fixed position of the PCB.

4) Curing Furnace

SMD adhesive should be solidified to ensure that surface mounted components and PCBs are securely

adhered together.

5) SMT Reflow Oven

Surface mount components are firmly adhered to the PCB by melting the solder paste.

6) Washing Machine

Remove any welding residues that may be harmful to the body of the person or the products assembled on

the PCB.

7) Test Equipment

Check the quality of assembly and welding on the SMA (surface mounting assembly).

SMT Assembly Line Ways

SMT production lines can have different assembly methods depending on the type of assembly object,

assembly process, and assembly method.

1) Single Line Form

It is generally used to assemble SMC/SMD PCB assemblies on the surface of one PCB.

2) Dual-Line Form

The PCB is surface assembled with SMC/SMD.

3) Mixture Form

Inserts and mountings are available for the assembly.

4) Integrated Form

SMT integrated assembly system with feeding trolley controlled by computer.

SMT Production Line Process

A SMT production line includes the following steps.

• Printing: Solder Paste or Patch Tape printed on the pads of PCBs to prepare for

soldering components.

• Glue Dispensing: Glue falls onto the fixed position on the PCB. When using wave

soldering, the function is to fix components onto the PCB.

• Mounting: Surface mounted components are installed precisely to the fixed position on

the PCB.

• Curing: Cure the SMD adhesive to ensure that surface assembly components are securely

adhered to PCBs when using SMD glue.

• Reflow Soldering: Melting solder paste causes SMT components to stick on the PCB.

• Cleaning: Remove any welding residues such as flux that may be harmful to the body of

the user or the products assembled on the PCB.

• Inspection: Inspecting the quality of assembly and welding on the SMA (surface

Assembly Assembly) assembled.

• Return to repair: The return for repair has detected an SMA fault.

SMT Production Line Characteristics

SMT production lines have the following features:

• High Degree of Automation

The SMT line is equipped with a large number of automated machines, which reduces manual work and

improves production efficiency and quality.

• High Productivity

SMT production lines are more efficient than traditional plug-in production systems.

• Low Cost Product

SMT production lines reduce labor and material costs. This can lower product costs.

Use of SMT Production Lines

SMT production lines are widely used in the manufacture of electronic products such as mobile phones,

computers, TVs, and automotive electronics.

Trends in Development of SMT Production Line

The following are the main aspects of SMT production line development:

High-density: SMT production lines are also moving towards high-density as electronic

products become smaller and more intelligent.

Multifunctionality: SMT production will become multifunctional in order to meet the

demands of various products.

related Posts

Contact us

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Teams: alek_youte

Email: sales@yt-electronic.com