PCB Damage and Deformation: Causes and Methods for Improvement

This article analyzes the causes of PCB deformation and damage, as well as how to prevent board bending and warping behind the board.

Table of Content

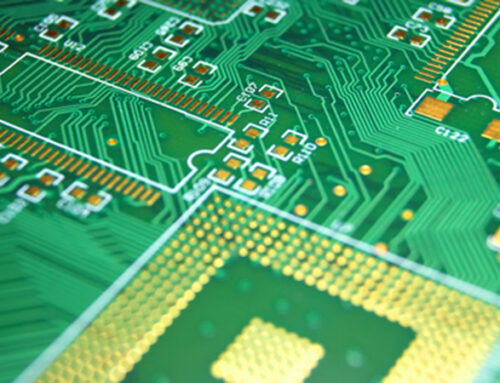

The flatness of a printed circuit board is critical in an automatic surface mounting production

line.

The unevenness of the PCB will result in component positioning deviations. This will impact the correct

connection or insertion of components into the holes and pads on the circuit board. This misalignment

can damage not only the automatic cassette loading machine, but also the soldered components of the

circuit board. It can also damage the alignment and the feet of the component. Uneven circuit boards can

also be difficult to install in sockets within the machine or chassis, which causes a lot more

inconvenience for assembly plants.

Surface mount technology is evolving towards higher precision, faster speeds, and greater intelligence.

This has led to more stringent standards for PCB board flatness. The PCB board is made up of resin,

glass cloth, and copper foil. The materials are different in terms of their physical and chemical

characteristics, which can result in thermal stress and deformations during the lamination. The high

temperatures, mechanical cutting and wet processes that PCBs go through during processing can also have

an impact on board flatness. PCB manufacturers face a complex challenge due to the many causes of PCB

deformation. This includes differences in material properties, processing techniques, and more.

In order to analyze the causes behind PCB deformations, it is necessary to consider multiple

factors, such as material, structure and pattern distribution.

This article will analyze and explain various causes of deformation, and provide solutions to them.

Uneven distribution of copper foil can lead to board deformation and bending in circuit boards. The

circuit board is usually designed with a large copper foil area as the ground layer. Sometimes, the Vcc

layer can also be designed using a large copper foil area. The copper foil will not be evenly

distributed over these large areas causing inconsistent heating and cooling. The circuit board will

expand and contract due to thermal expansion. If the expansion is not evenly distributed, this will lead

to stress differences and deformations in different parts. The circuit board will soften if the

temperature reaches its glass transition temperature.

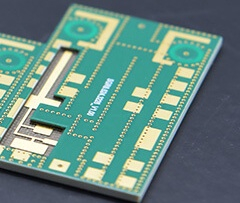

The current printed-circuit board designs use multilayer structures with connection points (through

holes) between rib pins. The three main types of connection points are blind holes, through holes and

buried hole. The location of the connector point can have a limit on the expansion or contraction of the

board. This may cause it to warp or bend. During a normal reflow operation, the board will be driven

both on the front and back by chains in order to preheat it. The defect is visible when the board

becomes too heavy or large for support. A depression can appear in the center.

What are the best countermeasures for preventing board bending or warping behind a

board?

Temperature is a major factor in plate stress. Its changes can have a large impact on plate stress. The

board’s bending and warping can be reduced by lowering the temperature in the reflow oven or

adjusting the heating/cooling rates. This move can have other negative effects. High Tg sheets are

sheets that have a higher glass-transition temperature. This is the point at which the material changes

from a glassy to a rubbery state. Boards with a lower value of Tg will soften more quickly after

entering the reflow, but will take longer to reach the rubbery state. This will result in greater

deformation. A plate with a high Tg value can be used to increase the board’s ability to resist

stress and deformation, but it will also cost more.

To achieve lighter and thinner designs in electronic products, the thicknesses of circuit boards have

been reduced from 1.0 mm to 0.8 mm or even to 0.6 mm. It is therefore difficult to maintain the flatness

in the reflow-oven. It is recommended that in the absence of professional guidance on thin circuit board

thickness, a minimum of 1.6 mm be used to reduce the risk of deformation. Reduce the size of the board

and reduce the number of splices to further reduce distortion. The circuit board relies mainly on chains

to advance in the reflow-oven, and its weight can cause deformations. The long side of the board should

therefore be parallel to the chain of the reflow-oven as much as is possible in order to minimize

deformations caused by its weight. This consideration is also used to reduce the number of parts.

According to the claim, the smallest deformation of dent can be achieved by using a shape as similar as

possible as a narrow vertical oven.

related Posts

Contact us

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Teams: alek_youte

Email: sales@yt-electronic.com