How to Select a PCBA Manufacturer that Is Suitable for Your Product

This article mainly explains how to choose a suitable PCBA factory from four aspects: PCBA factory professionalism, service awareness, industry experience.

Table of Content

Customers don’t always know where to find PCB assembly in Shenzhen. There are many printed-circuit board assembly factories

in Shenzhen that look the same on the outside.

Choose a PCBA manufacturer with a high production capacity. How can we choose a custom PCB maker that is

suitable for our needs? Consider the following Points.

Specialization of PCBA Factories

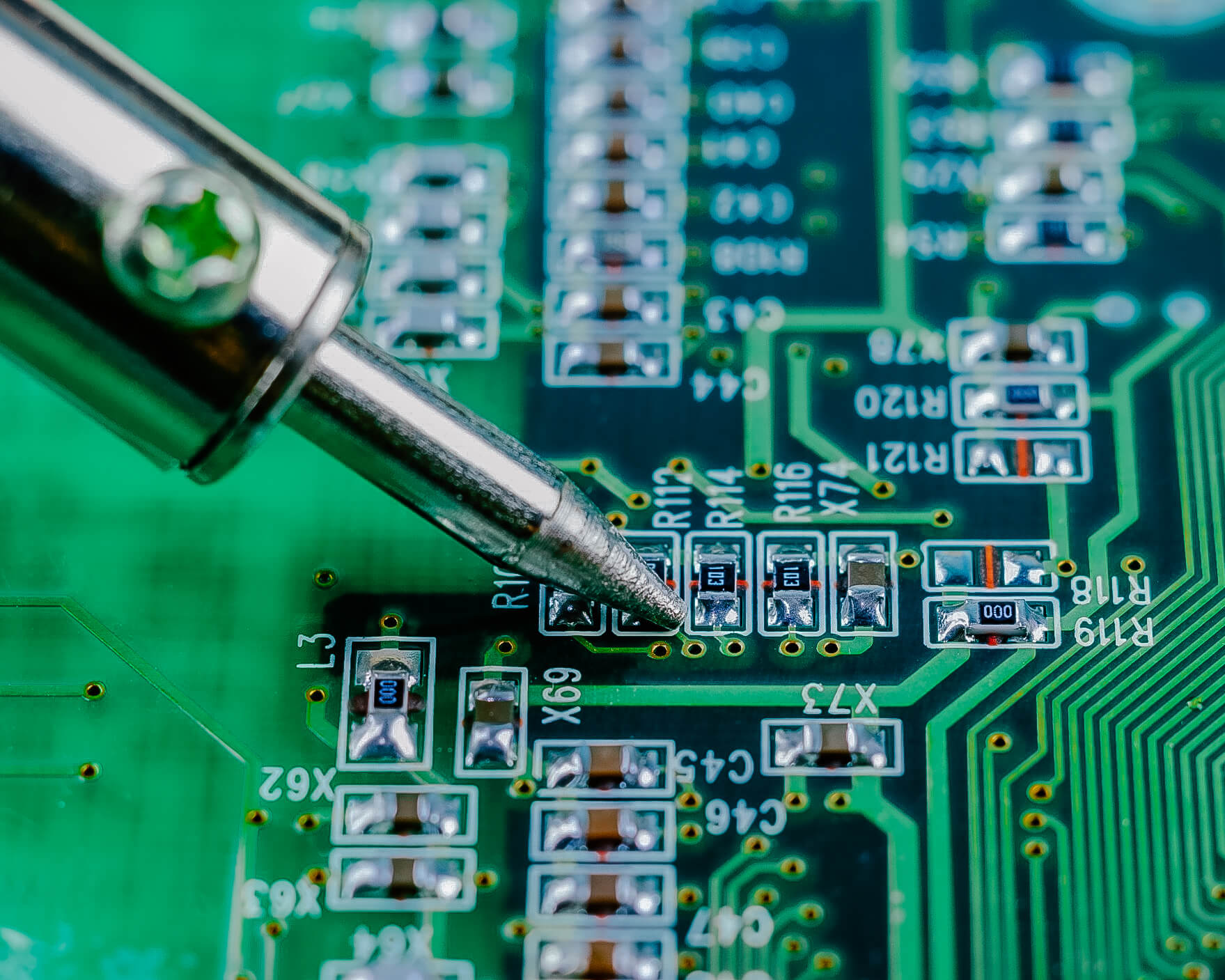

1) Check the Production Equipment at the Factory

A complete PCBA line will include a

solder paste print, SMT placement machines, reflow and wave soldering equipment, an AOI detector and ICT

online tester.

2) Equipment Processing Capabilities

You should ask about the processing capability of each device, and whether it meets the requirements of

the circuit board. For example, what is the minimum package size that the pick-and-place machine can

handle, or the maximum width and spacing of the prototype PCB boards that can be processed by the production line?

3) Check Qualifications

• You should check if the PCBA factory you are considering has ISO9001 certification for quality

management systems.

• Is PCB assembly and production in accordance with IPC-A 610F standards?

• Do you have any SOPs or other documents that guide your circuit board production?

The completeness of the documents reflects the professionalism and quality of the factory. You can

understand the level of production quality management by checking the data documents and certification

qualifications.

Service Awareness

PCBA is more than just cold product processing. People are still alive, even though machines are no

longer working. The importance of service cannot be overstated! You can save time and effort by working

with a professional assembly service and a quick turn PCB assembly.

PCBA manufacturers who have a strong sense of corporate service. It can be proactive and help solve

customer problems quickly when problems arise. Understanding the culture of the PCB board maker and

their attitude towards customers will help you understand how service-conscious they are.

Experience in the Industry Is Important

It is hard for a PCBA manufacturer without strength to survive in the PCBA industry. If you know the

operating hours of the factory and how many products it processes, as well as the difficulty in

processing those products, then you can determine if the PCBA factory is right for your needs. Choose a

PCBA manufacturer with a lot of industry experience who has worked on products similar to yours.

PCB Board Price

PCBA processing can be done in a relatively transparent manner. Prices are high and low. You should be

cautious if the quote is too low. The cost of processing will be higher if you purchase original

electronic components through formal channels. Some PCB board makers choose to use second-hand and fake

materials in order to save money, but this will negatively affect the product’s quality and

stability. Don’t focus too much on low-cost PCB production. Choose a PCBA manufacturer that is

cost-effective and based on mutual benefit and win-win situations.

related Posts

Contact us

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Teams: alek_youte

Email: sales@yt-electronic.com