Applications and Types of Printed Circuit Board

It is crucial to understand the distinction in between PCB production and its assembly procedure.

Table of Content

What Are the Different Types and Applications of PCAs?

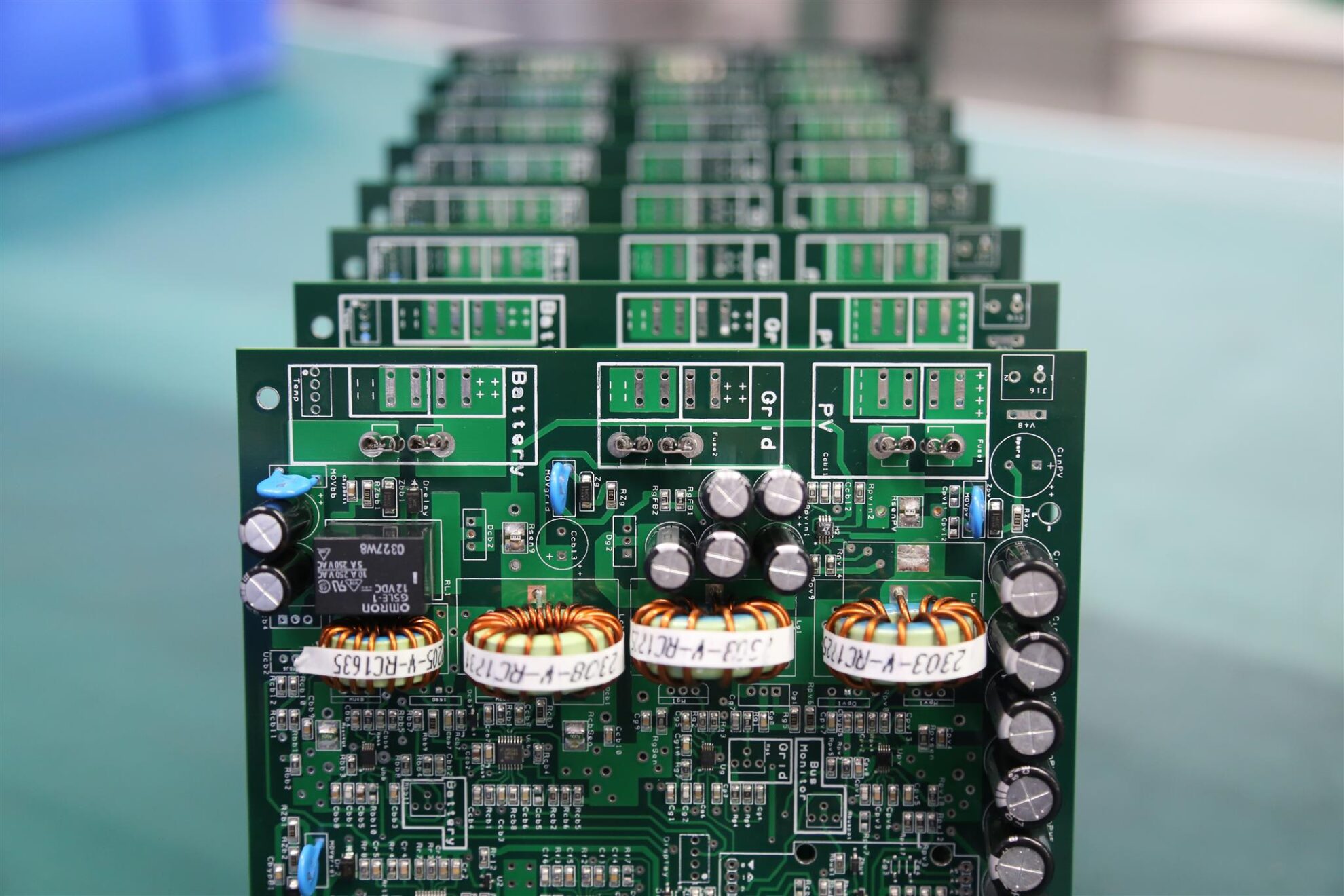

A printed circuit board is commonly used in electronic products as a base for wiring and socket

components that are mounted on the surface.

Photolithography is used to create PCBs in applications that require fine wiring such as computer

systems. This process is a scaled up version of the way connections are made on processors.

Solder is used by machines to attach electronic devices to the PCB. In an industrial microwave, the PCB

is heated to melt the solder connecting the components. The majority of PCBs consist of glass-reinforced

or fiberglass polymers and copper traces.

PCBs used for simple electronic devices have a single layer. Up to 12 layers can be found on complex

electronic printed circuit boards such as motherboards or digital graphics cards. PCBs can be any color,

including green.

PCBs connect electrical components using copper tracks, unlike ordinary wires. Electrical components are

secured by drilling holes into the board. Soldering is used to secure them, and copper tracks are used

to connect them into a circuit. A PCB assembly is the combination of a PCB (printed circuit board) and

its components. The PCB would be a useless board without this assembly. Its importance is obvious.

PCBs can be found in nearly all electronic devices that we use and see every day. These PCBs are

responsible for making devices that we use every day look smaller, while still containing more

technology. Applications include:

• Radios and TVs

• Computers

• Alarm systems

• Coffee Machines

• Washing machines

• Playstations are a great way to play games.

• Mobile phones

• Ovens

The other application areas include medical and industrial components, as well as military (bikes,

automobiles, planes, etc.).

Overview of PCB Manufacturing Process

Understanding the differences between PCB assembly and PCB manufacturing is essential. PCB assembly

production involves PCB design, prototyping and PCB mounting.

We will now take a closer look at PCB production.

Board design, component procurement and assembly are the three main PCB manufacturing processes. Design

for testability (DFT), and design for manufactureability (DFM) is essential to ensuring the best return

on the project costs, whether the PCB production and assembly is for large or small batches. Assembly of

a PCB can vary, unlike manufacturing. It depends on your preferences or application.

related Posts

Contact us

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Teams: alek_youte

Email: sales@yt-electronic.com