Flexible PCB is a flexible printed circuit board that can be folded or bent and is used for static and dynamic applications.

Flexible Circuit Board Reinforcement

Flexible PCBs are in high demand across all industries, but especially the military, industrial, and medical sectors. Due to the small volume of these parts, yt-electronic is able to handle many orders for flexible PCBs that are both high-mix and low-volume.

What Is a Flexible PCB?

The name "flexible printed circuit boards" (also called FlexPCBs), comes from the fact that they can be designed to fit any electronic device or product. Flex boards have patterned printed circuits, and base materials that are ductile. This allows them to highlight component arrangement.

We will also consider how flexible PCBs are connected to other devices. We will now discuss the use of stiffeners when designing Flexible PCBs.

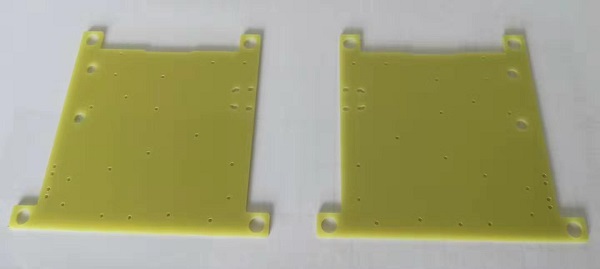

Materials commonly used for flexible PCB stiffeners include Fr4, PI and aluminum.

When Using Reinforcement

You can use stiffeners to reinforce the areas where you will be assembling components, but not in the places where your board will bend. You need stiffeners both on the front and back of your board where it bends. Two laminates may be needed. Some stiffeners may require an additional lamination cycle. The stiffeners add thickness to the board, and they also affect manufacturing costs and time. In some cases, stiffeners may be necessary.

Pure-flex PCBs are able to accommodate fewer parts than rigid-flex components. The rigid part of a rigid-flex circuit assembly can be just as complex as traditional rigid circuit boards. Sometimes stiffeners and coverings are laminated together.

Reinforcement Material for Flexible PCB

Kapton or FR-4 are used as stiffeners. When the end of a flexible line needs to be extended and inserted into ZIF connectors, Kapton is used. However, Kapton is only suitable for a single lamination cycle. The same lamination process can be used to complete FR-4 stiffeners.

Use Stiffeners to Route and Fix Flexible PCBs

The stiffener material will be used to secure the array. The array becomes harder.

In the following cases, flexible PCB stiffeners are required:

• Components in dynamic or active bending zones near

• The component's weight and size puts pressure on its flexibility

• Planarity is critical when there are many SMT pads.

• Connectors with repeated insertion or assembly need stiffeners or parts to relieve stress on the backing plates.

In the Following Situations, Reinforcement Is Not Necessary:

• The flexibility of the PCB is not affected by smaller "static" components. The flex area is no components.

• Flexible PCB Design Techniques

What Are the Benefits of Flex Cables Over Cables?

Flexible PCBs offer several advantages to cables.

We have discussed both the advantages and disadvantages. Flex PCB's higher initial cost will reduce overall costs. Flexible PCBs are produced in days, whereas cables can take several weeks. A flex circuit can reduce or eliminate cable costs and assembly time. It also produces a lighter product.

What Is the Recommended Hole and Pad Size for Flexible PCBs?

Flex materials, like Kapton do not drill as well. Flex is the only material that can be used for minimum sizes of ten mils or more. The rigid-flex PCB specification is similar to the rigid board specification. The only place where the flex board is plated and pad size are for the barrel (hole walls). Due to the need for bending and keeping the copper electrodeposited away from the surface, the flex holes do not have a surface plating.

Elastic Pre-Preg

The preferred bonding material to join flexible and rigid materials is no-flow prepreg. Most commonly, it is standard FR-4 polyimide.

What Alternative Materials Can Be Used to Join Flexible and Rigid Materials Together?

The preferred bonding material is No-flow prepreg. Available in polyimide or standard FR-4.

How Does a Real Stack Look?

The rigid board has the same planar layers as the flexible layer.