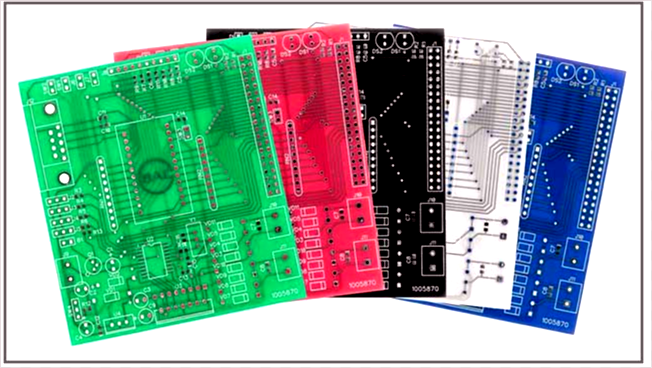

PCB circuit board can be produced in any colour you choose.

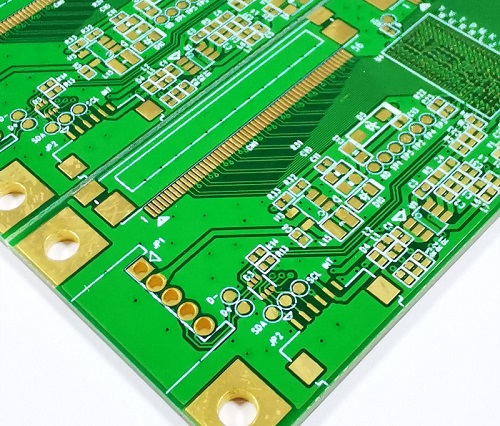

It is not the actual circuit board that is green but rather a printed material known as solder mask. This is a solder-resistant layer. This layer is applied to the areas of the board where solder should not be collected. This prevents the formation of solder bridges between IC pins. It can help prevent large amounts of solder from being picked up by the board in the older eras when wave soldering was used.

The green pigment is used in the resin formula. Green is used as an additional tool for the manual inspection of PCBs. Manual checks may be required even though most checks are automated. Green solder masks are standard and perform slightly better than other colors. Green is the standard color for PCBs. It may be important in dense designs but it's not a big deal on most PCBs. You get the default color unless you specify otherwise.

The green you see is the solder mask color. It is on the topmost component layer (to prevent shorts and soldering mistakes, etc.). It's not clear why solder masks tend to be green. Here are some theories.

• The raw resin is green. In the initial stages of PCB manufacture, it is melted to create the solder mask.

• The color green is a military standard or test.

• Under different environmental conditions, green is the best color for the background to contrast white silkscreen text.

Most PCB manufacturers advertise that they are able to produce boards in all colors of soldermasks.