Surface Mount Technology (SMT) is the most common method used to manufacture electronic devices.

SMT has the main benefit of being able to fit more components onto a printed board. This improves device performance and functionality.

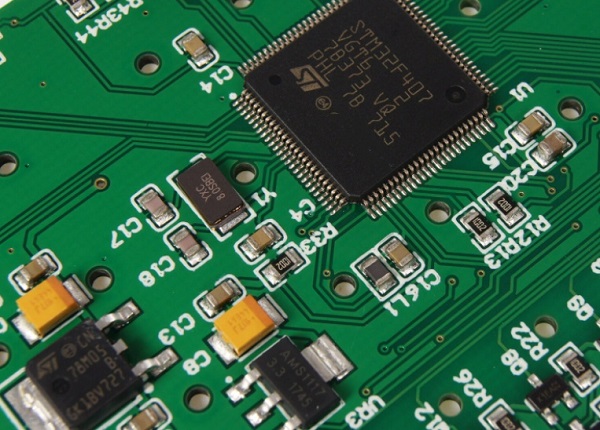

When using SMT, components are attached directly to the PCB surface instead of being inserted through holes.

This method allows the components to be mounted both on the front and back of the board. It greatly improves the space usage of the board.

With the development of SMT, however, new challenges also have emerged. With components becoming smaller and smaller, soldering and precise placement are needed.

Due to the increasing component density, makes troubleshooting more difficult and repairs more complex.

The Challenges of SMT

1. PCB Design Optimization

Surface mount assembly is the process of placing components directly onto a PCB's surface, rather than through holes.

This method is quicker, more precise and less expensive compared to through-hole assembly, but it requires careful design optimization in order to ensure that the assembly process works.

Circuit designers must consider the best way to connect and layout components in order to increase the performance of the circuit.

2. Placement of Components

The key to a successful SMT assembly is proper component placement. Place components in an easy-to-follow, logical order.

Place similar components together. This will reduce the amount of vias needed and improve the electrical performance.

As components become smaller, it becomes more difficult to solder and place them precisely. It requires advanced equipment, technology and higher levels of operational skill.

3. Avoid Overcrowding

Overcrowding of components will increase the likelihood of error and reduce the yield.

It can be difficult to test or troubleshoot a board once it has been assembled if the board is overcrowded.

4. SMT Global Competition

To gain a greater market share, countries are working hard to increase their production capability and technological level. To maintain their competitive edge, enterprises must continuously innovate and improve.

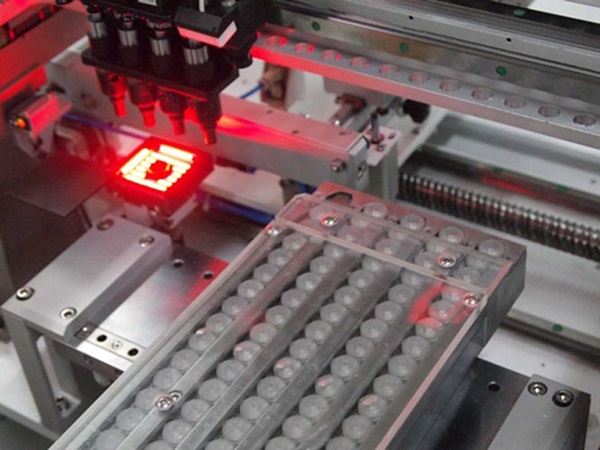

With new technologies it is now possible to automate SMT production lines and SMT patch machines.

PCB assembly has been revolutionized by the new standards of production, efficiency, and quality. To stay competitive, companies must constantly adapt and learn new technologies.

Summary

Despite the challenges that SMT faces, it remains an important part of electronic device manufacture.

We are confident that through continuous innovation and improvements, we can overcome these obstacles and continue to propel the electronic device manufacturing sector forward.

As we confront these challenges, remember this: Every challenge is an opportunity. Each problem can be solved.

Each challenge is an opportunity for us to grow. We can only overcome challenges and grasp opportunities through constant learning, innovation, and practice.

We expect more innovation and breakthroughs to occur in the SMT industry. We are confident that we will find and implement solutions, whether it's in the areas of design optimization, component positioning, avoiding crowding, global competition or the introduction new technologies.

We also hope to see more individuals and companies involved in this industry. We can only promote this industry's development and make greater breakthroughs if we all work together.

In short, SMT offers many challenges and opportunities. This field is only open to those who are willing to take on challenges and grab opportunities. Together, let's look to the future of SMT!