The PCB assembly process is the assembling of PCB board, components, electronics and so on. As a PCBA Process Engineer, I will explain the various steps in the PCB Assembly process:

1. Design: Create PCB drawings that meet the functional requirements for electronic products. This includes component location, pin spacing, pin size, hierarchical structures, etc.

2. Circuit board processing: Circuit board processing is the process of converting PCB drawing into the shape and circuitry of the circuit boards.

3. Circuit board manufacturing: Circuit board manufacturing is the process of printing circuit boards and graphics onto PCBs.

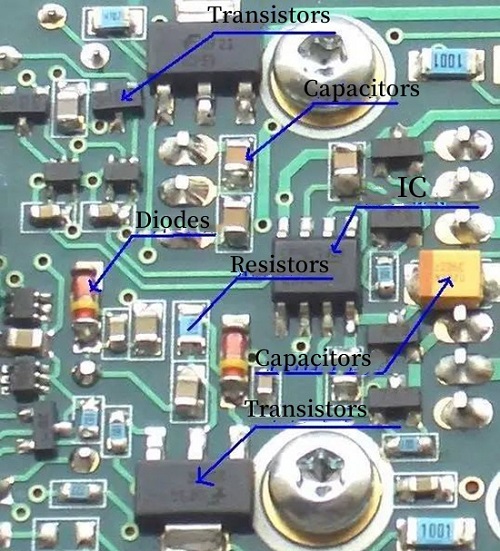

4. Electronic Components Souring: Purchase the components required for the PCB according to its design, including resistors and capacitors.

These components are purchased according to electronic component list (BOM).

5. Mounting components: Attach the components to the PCB.

Component placement includes:

Manual placement: Components can be manually placed on the PCB.

Automated placement: Place components on the PCB using an SMT machine.

6. Soldering: Solder components to PCB.

There are many different welding methods.

Wave soldering: Heat and melt solder paste in order to attach components to PCBs.

Reflow Oven : heat and melt solder paste in order to solder components to PCB.

7. Inspection: Check the PCBA for compliance with the specifications.

The following methods are used to inspection:

Appearance Inspection: Check the appearance of the card to see if it has any defects.

Function Testing: Test the PCBA to see if it functions properly.

8. Packaging: Prepare the PCBAs for transport and storage.

Common Issues that Can Occur During the Assembly of Printed Circuit Boards

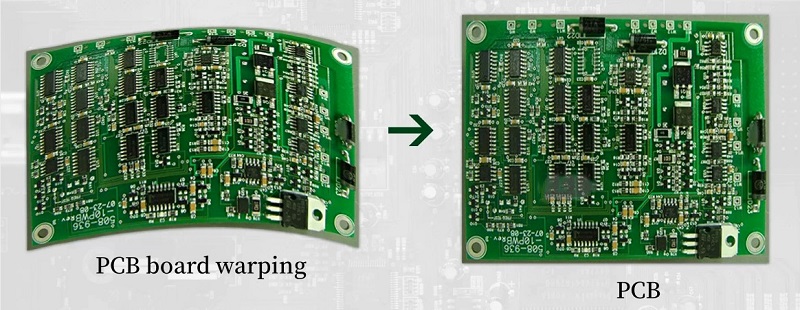

Some of the common problems encountered in PCB manufacture include PCB warping deformation cracks on PCB boards short circuits on PCB lines etc.

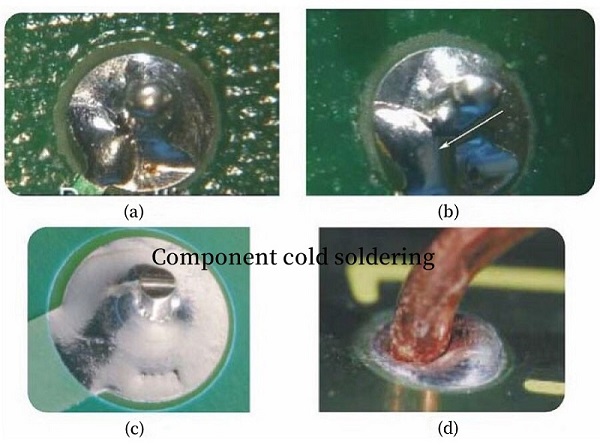

Common problems in the component placement process: component misalignment,component cold soldering, component desoldering, etc.

Problems that occur in the welding process include: cold solder joints, desoldering, porosity of solder, contamination of solder.

The PCBA production process requires a thorough understanding of these issues. It also demands the timely detection and resolution of any problems and the assurance that PCBA quality meets requirements.

Summary

To ensure high-quality electronics, the PCBA process demands a thorough knowledge of each step and strict quality control.

The process engineers must monitor each step and solve any problems that may arise. This will ensure that the PCBs produced meet the required performance and reliability.