Surface Mount Technology ( SMT )

SMT is an important technology in PCB assembly. It is now an essential part of modern electronics manufacturing.

This has had a major impact on the design of electronic equipment and led to a revolution in electronic manufacturing.

SMT is a more advanced technology than traditional through-hole technologies.

Instead of inserting through holes into the PCB, electronic components are mounted on the surface of the printed circuit board (PCB).

This innovative approach allows for more efficient, compact and feature-rich electronic manufacturing.

SMT offers many advantages over traditional through-hole technologies.

First it improves layout density on the circuit board. This allows more electronic component be arranged within a small space.

Second is the automated production process using SMT technology. This improves manufacturing efficiency and reduces costs. It also makes electronic products more competive.

SMT also allows for better soldering quality and reliable connections. This improves the reliability and stability of electronic products.

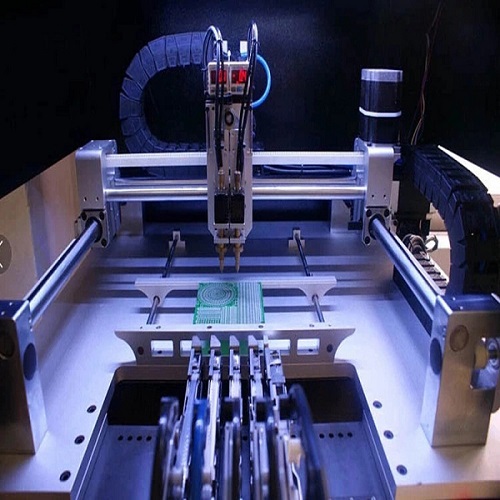

A surface mount machine is an important automation tool in the SMT implementation process.

Surface Mount Machines are capable of quickly and efficiently mounting components on PCBs using advanced control and mechanical technology.

The automated assembly process improves productivity, reduces errors and increases product quality.

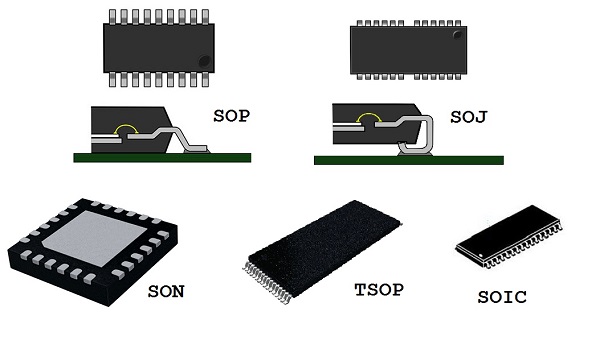

Surface Mount Devices

Surface Mount Devices are crucial in electronics manufacturing.

Modern electronic products are not complete without it, due to its unique design and performance.

They are usually smaller and thinner compared to traditional plug-in devices. They have a greater level of integration, and they are better at high-frequency characteristics. This allows for more flexibility in designing and performing electronic devices.

Surface mount devices are made up of a variety of components, including chips.

Components such as surface-mount resistors, capacitors and play an important role in electronic circuits. These components are small, elegant and meet the need for compact designs while still maintaining high electrical performance.

This allows electronic products to perform more functions in a smaller space and improves overall performance.

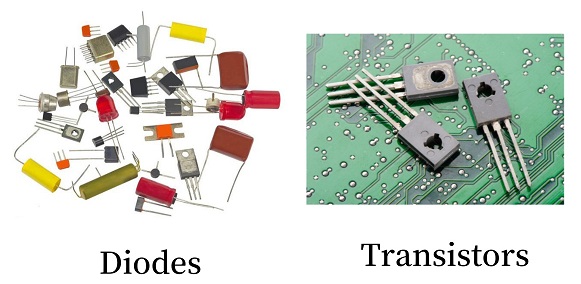

Surface mount devices, in addition to chip components include transistors, diodes and integrated Circuits.

They perform a variety of tasks in electronic devices from controlling currents to complex computing functions.

Electronic products are more portable due to their miniaturization and lighter weight, which meets the needs of modern society in terms of portability and performance.

Surface mount devices are smaller and more compact than traditional plug-in components. They also improve the layout density of the PCB board.

This allows for more freedom when designing electronic devices and can lead to innovative and personalized designs.

The automated production process using Surface Mount Technology can reduce manufacturing costs and improve the competitiveness of electronic products.

Surface mount devices, which are constantly evolving and improving in the electronics industry have led to the improvement of performance and diversification of products.

The application areas of the equipment include consumer electronics, medical care, communications and other industries. This provides strong support for design and manufacture.

The miniaturization of devices, their lightweight and high performance characteristics will continue to drive the electronic technology development trend. They will also lay the foundation for future innovations.

SMT has improved the density of layouts on circuit boards and reduced the size of electronic products.

The SMT technology is not only more efficient in production, but it also modernizes the electronic manufacturing process.

Surface mount devices can be quickly installed with the aid of automated equipment such as surface mounting machines.

The rapid growth of the electronics industry has been accelerated by the close relationship that exists between surface mount technologies and devices.

Future electronic products are expected to be lighter, smaller and more powerful.