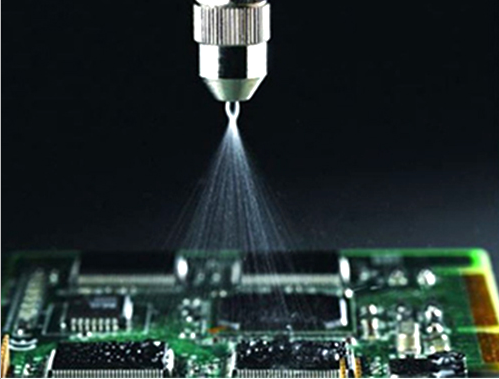

The PCB conformal coat can increase the durability and reliability of circuit boards in harsh conditions.

Paints Conformal Coating Requirements

1) Paint Film Thickness

The dry film thickness ranges from 25um-40um.

2) Second Coating

After the paint film has cured, a secondary coating can be applied to ensure that the product with the highest protection needs is coated thickly.

3) Check and Repair PCB

Repair any defects and check whether the circuit board is coated according to the required quality. Conformal coating is applied to the pins, and other areas that are protected.

Use tweezers or a cottonball dipped into water to clean it. When scrubbing, be careful not to remove the correct paint film.

Component replacement. If you wish to replace a component after curing the paint, you may do so as follows:

• Solder the components directly with an electric soldering tool. Then, use a cotton cloth dampened in board cleaning solution to clean around the soldering pad.

• Soldering replacement components.

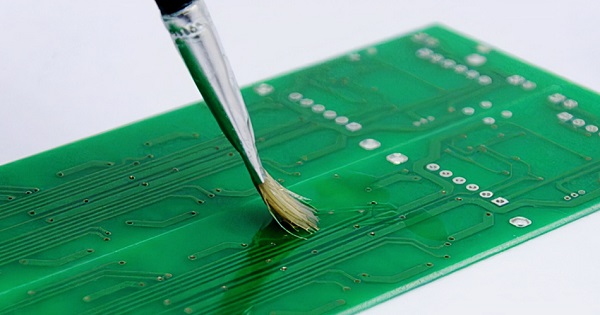

• Apply the three-proof painting to the welded parts using a brush. Wait for the film to solidify and dry.

Operation Requirements

1) Workplace Requirements

It is essential that the workplace for conformal coating be dust-free and free of flying particles. The workplace must have excellent ventilation and non-staff entry is prohibited.

2) Operator Protection

Wearing protective gear such as rubber gloves, a gas mask, or chemical-protective glasses is mandatory when operating. This prevents injury to the body.

3) Clean Up after Work

Close the container tightly after cleaning the tools.

4)Anti-Static

Circuit boards should be treated with anti-static. Do not overlap the circuit board. The PCB must be horizontally placed during the coating process.

Quality Requirements

1)Paint Film Surface Requirements

The surface of the board should not have any paint dripping or flowing. Avoid dripping paint onto isolated parts when applying it with a brush.

To protect pads, SMT components or conductor surfaces, the conformal coating must be bright, smooth and uniformly thick.

2)Paint Film DefectRequirements

Paint surface and component surfaces must be free of defects, foreign objects, such as bubbles and pinholes.

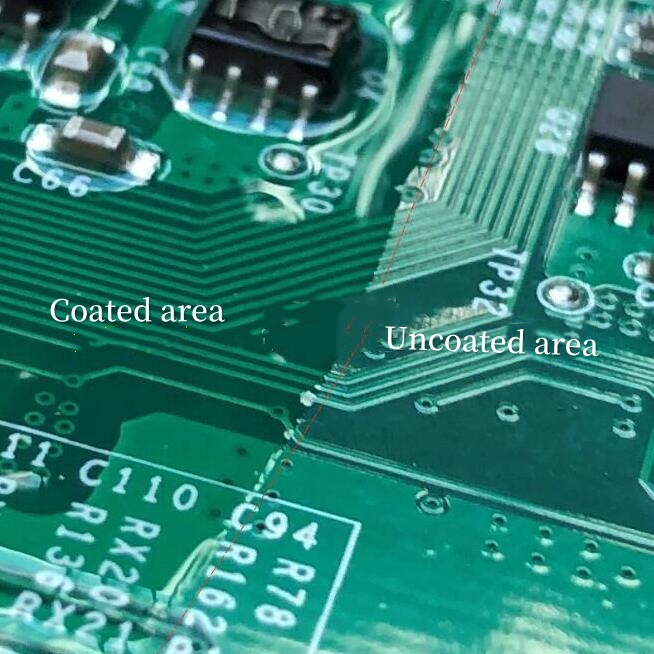

3)Non-Coatable Parts

Conformal coating should not be applied to isolated or localized components.

Parts and components which cannot be coated by conformal coating

Non-coated conventional devices include: painted high-power radiators or heat sinks; power resistors (high-power diodes); potentiometers.

4)Special Case Coating

The RD department will determine the coating requirements, or can apply the three-conformal coat as shown on the drawing.

There are other parts and components which cannot be painted with three-proof paint, as shown in the drawings. These components can be found in the "Catalogue of Non Proofing Components" (Areas).

Summary

Shortly, conformal coatings are a crucial process. To ensure safety and reliability, it should be done according to the specifications.

It can improve efficiency and reduce maintenance costs by ensuring the quality of circuit boards.