Abstract

The pre-reflow AOI is a technology that uses automatic optical inspection to inspect printed circuit boards prior to the reflow oven during the SMT assembly.

Pre-reflow AOI is a pre-reflow inspection that uses optical processing to analyze the image and determine if there are any defects, such as wrong parts, missing parts, offsets, reverses, etc.

Principle

1) Image Processing

The core technology for pre-furnace A.O.I. is optical image processing. This technology can convert an image from a circuit board to a digital image, and then analyze that digital image.

The main optical image processing technologies that are used in pre-reflow AOI include:

• Image matching technology: The circuit board image is compared to a standard image in order to determine if there are any defects.

• Image Analysis Technology: By analysing the image of a circuit board and identifying its location, shape and size, as well as judging if there are defects.

• Image feature detection technology: Identify defects in circuit board images by identifying the features.

2) Software Analysis

The software analysis component is also a significant part of the pre-furnace A.O.I. It is responsible for analysing the image and determining if there are any defects.

The main features of the software analysis system that is used by the furnace-front AOI are:

• High Precision: Can accurately identify defects.

• High Speed: Images can be processed quickly.

• Scalability: can be expanded to meet the needs of various products.

Test Items

The following defects can be detected by AOI prior to the furnace:

• Missing Components: components missing from circuit board.

• Offset: Mounting components SMT in the wrong position.

• Reverse: The direction of component soldering is incorrect.

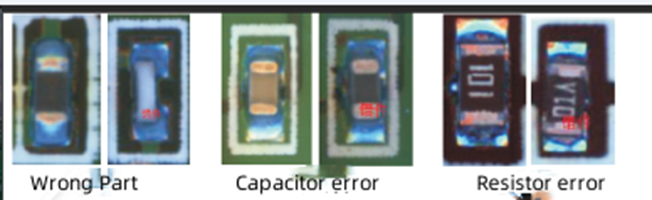

• The wrong parts: Using incorrect components on the circuit boards.

Application

Tablet computers are essential tools to work, entertain and for entertainment. Their quality standards are high. The AOI pre-furnace can detect and correct any problems quickly.

Modern information systems are not complete without servers. Circuit boards are complex and AOI pre-furnace can detect and correct any problems quickly.

The components of medical equipment are a vital part of ensuring the health and safety for the people. They require a high level precision.

Pre-furnace AOI is able to detect and correct any problems that may occur during the manufacturing of medical devices. This ensures the safety and reliability.

Pre-furnace AOI is required to detect and fix problems in time. Aerospace equipment must meet very high standards of quality.

Benefits

• Reduced PCB rework cost: The pre-furnace AOI detects problems like missing parts, misalignment and reverse polarity. This reduces the circuit rework time and costs.

• Reduced scrap costs: The AOI pre-furnace can detect defects that are not repairable, thus reducing scrapprices.

• Improving production efficiency: Furnace front AOI helps PCB makers identify and fix problems quickly, improving production efficiency.

Conclusion

The pre-furnace inspection is done before the parts are mounted. This can reduce PCB scrap and rework costs.

Increase production efficiency to increase product yields and reduce production costs.

Pre-furnace AOI has a wide range of applications and is an essential detection method for PCB assembly.