In the manufacture of electronic products, SMT assembly plays a major role. Gluing and filling processes are vital.

Pouring and gluing glue protects and packages electronic components. It also improves waterproofing, dustproofing, and shockproofing properties.

What Is the Difference Between Filling and Gluing?

The two processes of gluing and pouring adhesive are different.

Pouring glue is the same as gluing, except that you inject the gum directly into the space reserved.

The glueing is used to bond small areas. Pouring glue can be used to fill large spaces or areas.

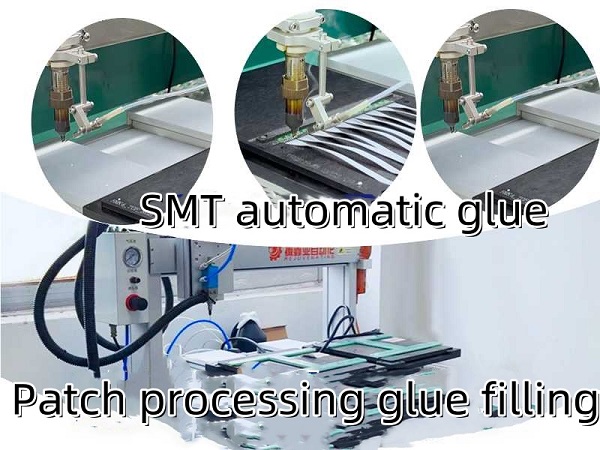

Method of Gluing Patches Processing

In the patch-processing industry, there are two main methods for gluing: dispensing or potting.

1) Glue Dispensing

The glue is dispensed by squeezing it through a nozzle or needle to the desired location. The glue dispensing procedure is easy and ideal for small batches.

Contact dispensing is the most common method, followed by non-contact dispensing.

• Contact dispensing The needle/nozzle directly contacts surface of adherends to squeeze out glue.

Contact dispensing has the advantage that it's easy to use. It is not precise and can cause bubbles.

• Non-contact dispensing Does not involve direct contact between the needle or nozzle and the adherend. The glue is squeezed out using air pressure or vibration.

Non-contact dispensing is more precise. The operation is more complex, but it is less likely that bubbles will form.

2) Potting

Potting is the process of injecting glue in a reserved area.

The potting method is ideal for large-scale production. There are three main methods of potting: mechanical, automatic, and manual.

• Manual Potting: Inject glue using hand tools into the reserved area. Manual potting is cheaper but less efficient and it's difficult to guarantee accuracy.

• Mechanical potting: Use a mechanical device to inject glue in the reserved area. Mechanical potting may be more efficient, but it is also more expensive.

• Automated potting: Inject glue using automatic equipment into the space reserved. The most efficient, but also most expensive method of potting is automatic potting.

Process for SMT Glue and Glue Filling

The following steps are generally involved in gluing and filling a patch:

1) Prepare the Food

This includes cleaning and selecting the right glue as well as configuring it.

Pouring or gluing: Select the method that best suits your needs.

2) Cure

Check the effect of the glue or pouring gum after curing.

Precautions when using glue in the patching process

You should take note of the following when gluing or filling SMT mounts:

• The adherend surface should be dry and free from oil, dust etc.

• The adhesive should be selected according to the material that will be adhered.

• Please follow all instructions when preparing the glue.

• To avoid bubbles, adhere or pour gum according to the manufacturer's instructions.

• After the glue has cured, it is important to check that the effect of the glue or filler meets the required requirements.

Use of Glue Fillings in Patch Manufacturing

The technology of SMT's pouring and gluing gum is widely used in the electronic product industry. This includes mainly these aspects:

Encapsulation of electronic components and protection: By gluing and potting, electronic components can be effectively protected from damage by water, dust and vibration.

Enhance the waterproofing and dustproofing performance of a product:Gluing or filling can improve the waterproofing and dustproofing performance of a product. It increases the life expectancy of the product.

Heat conduction and Insulation: Pouring and gluing gums can be used to improve the performance of the product.

Conclusion

The glueing and filling process is an important part of patch processing. It has a major impact on the performance and reliability of electronic products.

To ensure quality, it is important to follow all the requirements when performing SMT gluing.