The PCB Assembly Process Review refers to the audit of process documents, fixtures and first PCB prototypes during PCBA Manufacturing. It is used to determine if they meet the quality and production standards.

The List of PCBA Process Review's Contents and Requirements

1. Comprehensive Review Of Process Documentation

The PCBA process document includes the process flow, parameters, standards and other information.

During the review of the process, it is important to thoroughly examine the documents to make sure they comply with the following requirements.

• The flow of the process is complete and reasonable. It can meet the circuit board manufacturing requirements.

• The parameters of the process are precise and scientific. This can guarantee product quality.

• Process standards must comply with industry or national standards.

Focus on the following when reviewing documents related to process:

• Does the process meet the requirements for manufacturing the product? There are any steps missing or repeated?

• Check if the parameters of the process meet the performance requirements for the product and if there are errors.

• Check to see if the standards are in line with industry or national standards, and if there are any unreasonable or excessive requirements.

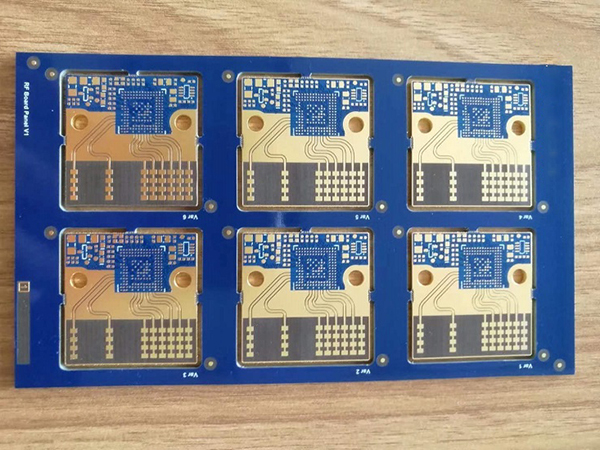

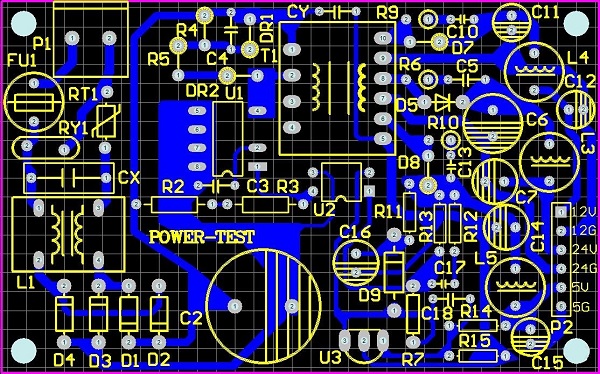

2. Review of the Circuit Board and Prototype

PCBA manufacturing is based on circuit boards and prototypes. During the review of the process, it is important to make sure that the PCBAs meet the following requirements.

• The circuit design is functional and free of defects.

• The components have been arranged in a way that facilitates production and maintenance.

• The pad design is reasonable and meets the welding requirements.

• There is no open or short circuit, but the line direction is correct.

It is important to pay attention to the following when reviewing prototypes and boards:

• Is your circuit diagram correct? Are there any design faults?

• Check to see if the component layout makes sense and if there are any conflicts or interferences.

• Check to see if the pad layout is reasonable, and if there are any welding defects.

• Is it the correct direction of the line? Is it a closed or a open circuit?

3. Conduct a Comprehensive Review of Fixture Design

Fixtures are important auxiliary tools for the PCBA fabrication.

During the review of the process, it is important to check that the design meets all the requirements.

• The fixture design meets the requirements for product manufacturing.

• Tooling and fixtures are made of materials that meet or exceed the requirements for use.

• The fixture must be able to meet precision requirements and have a reasonable processing technology.

It is important to consider the following when reviewing fixture design:

• Check to see if the design of the tooling or fixture is reasonable, and if there are any errors or defects.

• Is the selection of material for the tooling and fixtures reasonable and does it meet the requirements?

• The processing technology used in the tooling or fixture and its ability to meet precision requirements.

4. External Processing

It is important to assess the PCB outsourcing situation, as well as the capabilities and quality standards of the outsourcing manufacturer.

This determines if production and quality requirements have been met.

It is important to consider the following factors when evaluating outsourcing:

• The production capacity of the outsourcing manufacturing company should meet product demand.

• Does the equipment used by the processor meet the requirements for the manufacture of the product?

• Does the production environment meet the standards?

• Standardization of production management.

• Is the quality management system complete?

5. Methods Of Process Review

To ensure that the process review is effective, it should use methods that are proven to be successful.

Some of the most common methods for process evaluation include:

• Document Review: Conduct an extensive review of the process documents to make sure they meet the requirements.

• Physical Review: Examine the circuit boards and fixtures to make sure they comply with the requirements.

• Test Verification: Test the documents and objects to verify that they are in compliance with the requirements.

6. Records of Process Review

To facilitate future analysis and traceability, process reviews should be recorded clearly.

The following should be included in the process review records:

• Information such as the reviewer's name, date of review, and content.

• Review the findings and make recommendations.

• Review the conclusions.

7. Process Review Procedure

To ensure a smooth review, the process review should follow a defined procedure.

The process of craft review generally involves the following steps

• The preparation stage: Gather relevant information and create an audit plan

• Review Stage: Review of the Process Documents and Physical Objects

• Final stage: Present review conclusions and suggestions for improvement

8. Notes on Process Review

When reviewing the PCBA process, it is important to note:

• It should be thorough and detailed. This ensures that no issues are missed.

• The review must be fair, objective and free of personal bias.

• Reviewing products in a timely manner is essential to ensure a quick delivery.

Summary

The effectiveness of the PCBA review can be improved by tracking the results and conducting a comprehensive review.