In printed circuit board manufacture, FCT and ICT (In-Circuit Testing), are commonly used to test the quality of printed boards as well as electronic devices.

They differ in their test purposes, test methods and scenarios. This article will examine the differences between both test methods.

ICT(In-Circuit Testing)

ICT is a method of early electronic testing that is primarily used to detect errors in connection and soldering during PCB assembly. ICT has the following main functions and features:

1) Useful in PCB Manufacturing

In the early stages, ICT is used to verify the correct connection and mounting of the components. It's usually done after soldering, but before final assembly.

2) Point-Topoint Testing

ICT uses probes to test various connections points on the PCB. These test points are typically soldering or connection points of the PCB.

3) Detect Connection Problems

ICT circuit tests are designed to identify connection issues such as open connections, shorts, incorrect polarity etc. It can detect issues where components have not been inserted correctly, or soldered insecurely.

4) High-Precision Tests

ICT can provide highly accurate results, and detect small connection issues. It is a powerful way to discover circuit board manufacturing defects.

5) Unsuitable for Functional Testing

ICT is used primarily for connectivity testing. It is therefore not suitable for functional testing. It can't test the performance of a component or its functionality.

6) High Costs

ICT is more expensive in terms of test fixtures and equipment and has longer test times. It is therefore often used in production environments that require high quality connections, for example.

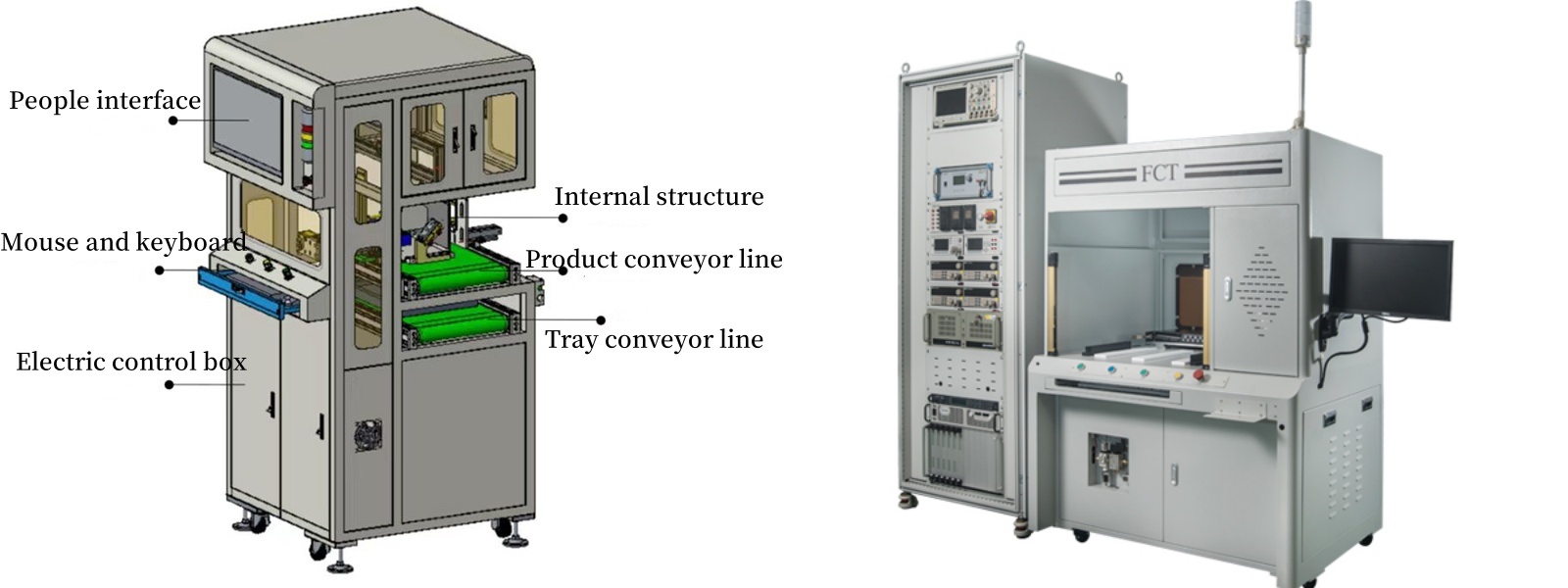

FCT Functional Circuit Test

The FCT test is more advanced. After ICT, it is used to test the performance and functionality of electronic equipment. FCT has the following main features and functions:

Final assembly testing: The FCT is performed at the end of PCB assembly, to verify that the circuit board meets specifications.

Functional Testing: FCT tests the functionality of the entire circuit board assembly. It checks the function expected according to the design specification.

Testing Connections: While the FCT is primarily focused on functional testing it can also detect connection issues such as loose cable connections.

Automated Testing: FCT uses automated testing equipment and test procedures in order to carry out tests quickly, efficiently, and repeatably. FCT is therefore suitable for PCB production environments with high volumes.

Detect entire performance: Tests the function of each component, but also the performance and the whole system. This includes the testing of device response time and power consumption as well as communication protocols.

Comprehensive testing: In comparison to ICT, FCT offers a more thorough inspection as it examines the overall performance and functionality of equipment.

Inspection Cost: While FCT is a more thorough test, ICT is usually more expensive.

Summary

We can see that ICT and FCT have different roles to play in the manufacture of printed circuit boards.

ICT is used primarily to detect welding problems and connection issues, while FCT tests the overall functionality and performance.

They are therefore often used in different stages of production, to ensure that electronic products are of high quality and reliable before they are shipped to the final user. The test method chosen depends on the type of product, production requirements and test objectives.

These two methods are usually used together in actual circuit board production to ensure high quality and performance.