Introduction:

Shenzhen is the hub of China's electronics manufacturing industry, and also a major center for scientific and technological innovation worldwide. SMT (Surface Mount Technology), patch technology has been widely used in Shenzhen.

The SMT technology is an important process in electronic manufacturing. It provides efficient and high quality solutions for the manufacture of various electronic devices.

Today, yt-electronic discusses the concepts and principles behind SMT patch technology, and the practical manufacturing process in Shenzhen. This will reveal the importance and impact this manufacturing technology has on the electronics sector.

The Principle and Concept of SMT Technology

1. SMT Is Based on the Following Principles:

The core principle of SMT is to attach electronic components (such as chips, resistors, capacitors, diodes etc.). SMT's core principle is to attach electronics such as chips, resistances and capacitances. The electronic components are attached directly to the PCB substrate, rather than passing through the hole. This method has many advantages, including higher assembly densities, shorter production cycles and lower manufacturing costs. SMT allows electronic components to be placed closer together on the substrate. This improves the complexity and performance.

2. The Key Elements of SMT

There are several important elements that you need to take into consideration in order to fully understand SMT technology:

PCB Design: We need a PCB design before we can manufacture SMT patches to determine the layout of the computer and its connection methods. To complete this process, engineers must be familiar with wiring rules and circuit diagrams.

SMT Machine: the SMT machine is a core piece of equipment. The SMT machine is used to

precisely place components on the PCB. SMT pick-and-place machines have a highly precise positioning

system that can perform many SMT operations quickly.

Soldering Process: After the components have been attached to the substrate they need

to be soldered to ensure that they are firmly fixed into the pad. This process is usually completed

using reflow ovens, which use hot air or infrared to finish the soldering.

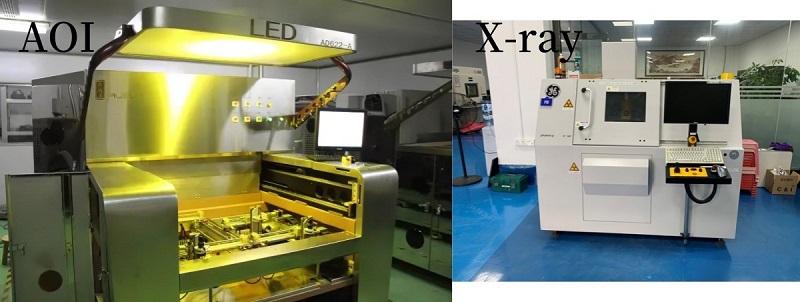

Control of Quality: The control of quality is essential throughout the entire manufacturing process. Visual inspections, X-rays, and automated inspection systems are used to ensure that components have been mounted and soldered correctly.

Shenzhen's Practical SMT Patch-Proofing Process

SMT-proofing is one of the core business activities of PCB manufacturers in Shenzhen. They provide customers with high quality prototype manufacturing services. This is a general process for SMT patch-proofing.

1. Demand Analysis

The customer will conduct a detailed analysis of the demand with the SMT service provider. This includes circuit diagrams (BOM), component lists, patch requirements, etc.

Ensure that you and your partner reach an understanding on the expectations and requirements of the project.

2. PCB Design

The SMT service provider will assist the client with PCB design if they do not already have one. They can also modify an existing design in order to meet the requirements of SMT patches.

This includes the component layout, pad design, routing rules, and so on.

3. Component Procurement

The SMT service provider can assist the customer in the purchase of electronic components after the PCB is designed.

To ensure that they have access to high quality components, they often have relationships established with several electronic part suppliers.

4. SMT Manufacturing

The SMT equipment can be configured to meet specific project needs.

The SMT placement machine then places the components on the substrate precisely according to the PCB schematic diagram. This process is fast and accurate, as it is highly automated.

5. Quality Control

The patch will be subjected to a strict quality check after completion.

We can check that the components are properly mounted, and the soldering is of high quality, by using X-rays, visual inspection and other methods.

6. Backcross Samples

We will send the samples for testing to the customer once the patches have been manufactured and passed quality control.

Customers can give feedback on any modifications or improvements that they feel are needed.

7. High-Volume Production

Only approved samples will be sent to the customer. Yt-electronic, the leader in SMT patch-proofing, is the brand to trust. We will continue to produce high volumes to meet customer market demands.

Why SMT Patches Need to Be Proofed

SMT technology is important in promoting electronics manufacturing. SMT is important in many ways.

1. Improve Production Efficiency

SMT technology with its high-speed production and automation features can improve PCB production efficiency and lower costs.

It allows companies to respond faster to the needs of customers and bring their products to market.

2. Increase Assembly Density

SMT allows for more components to fit into a small space, increasing the performance and functionality of electronic products.

The SMT technology is a powerful tool for miniaturization and light weight of electronic devices.

3. Cut Costs

SMT can improve manufacturing costs by reducing manual work and waste.

Reduced costs allow companies to price their products more competitively, resulting in a higher market profit.

4. Improve Quality

SMT technology's high level of automation and quality control can reduce human error and improve manufacturing quality.

For critical applications, such as medical devices or aerospace products, it is crucial to ensure that parts meet the high standards of quality and durability.

5. Innovation Promotion

SMT technology has been a major contributor to the advancement of the electronics industry.

SMT technology is constantly evolving, resulting in new materials, components, greater integration and smaller sizes. This provides a variety of innovation opportunities.

Shenzhen’s electronic manufacturing firms have played a key role in this area and have encouraged innovation in the global industry of electronics.

Conclusion

The SMT industry has grown in importance, particularly in Shenzhen. This is the centre of innovation and technological development.

SMT technology is important for improving production efficiency, increasing assembly densities, reducing costs and improving quality.

SMT will continue to be a major factor in the advancement of electronic products and innovations, as technology continues to evolve and market development continues. Shenzhen's SMT proofing business will continue providing crucial manufacturing support for electronics in different industries, and promote future technological development.