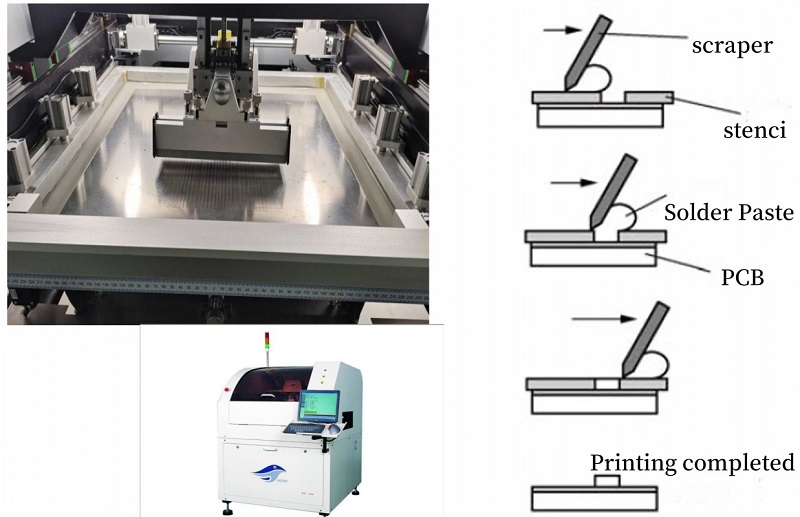

The SMT (surface mounted technology) printing technology used by the PCB factory is crucial and affects directly the quality of welding. When performing SMT assembly we must pay attention to printing quality. Use the SPI after the solder paste has been printed to check the quality of the print to avoid tin leakage and insufficient tin. These will have an impact on the subsequent surface mounted soldering.

Printing Technology: The Essential Elements

The mesh stencil, the printing material and the squeegee are its core elements.

Mesh/Steel plate: The printing effect is directly affected by the thickness, etching, size, shape and opening of the mesh/steel plate.

Printing Materials: They are mainly made up of adhesive and solder paste. The main solder used in flow soldering is solder paste, while the adhesive is used mainly in wave soldering or to stop components from moving. Lead-free solder is recommended.

Scraper: The pressure, speed and angle of the scraper, as well as its gap, have an impact on printing.

Select the Printing Method

When choosing a printing method, it is important to consider the type of PCB ( the HDI PCB or RF PCB,Flex-PCB are also options), component layout, surface treatment, etc.

Manual Printing: is a primitive printing method that can be used for applications which do not require a high degree of precision.

Semiautomatic Printing: This is a common printing method that has a low investment cost. It is ideal for applications requiring medium precision.

Fully automated printing: This printing method is most accurate, but it is expensive to invest in. It is best for applications that require high precision.

The Key Settings for 3d Printing Parameters

The parameters of printing include the blade pressure, speed, angle and gap.

Scraper Pressure: is the pressure applied to the scraper. determines how well the stencil fits the PCB. In general, the higher the pressure applied, the better printing results.

Printing Speed: controls the speed at which solder paste flows on the stencil. In general, the slower you go, the better your printing will be.

Angle of printing: is used to determine the pressure that solder paste will exert on the stencil. In general, the smaller angle, the more pressure.

Gap: Is used to determine the thickness of the solder paste. In general, the thinner the solder paste, the smaller the space between the stencil and the solder.

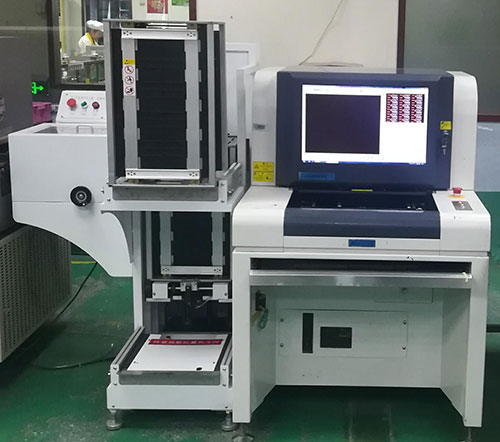

Printing Inspection: Vital Indicators

Print inspection is focused on precision, resolution and thickness.

Precision: Check the accuracy of the center position on the solder paste pad to avoid problems like incorrect component alignment.

Resolution: Check if the solder paste is printed in a regular shape to avoid problems like short circuits.

Thickness: To ensure welding quality, check the thickness of the solder paste.

Inspection Tools

Printing inspection tools include magnifying glass, micro balances and laser thickness gauges. They also have 2D/3D features on the printing press.

Magnifying Glass: Used for checking accuracy and resolution.

Microbalance: Used for measuring thickness.

Laser thickness gauge: This device measures thickness quickly.

Automated Inspection: Achieve automated thickness, resolution and accuracy.

3D Printer Function: Used to detect thickness with greater accuracy.

Summary

The printing technology is a key component in PCB manufacture and its quality directly relates to the quality of SMT soldering.

Select the screen/steel plates, printing materials, and scrapers according to the print process requirements. Set the parameters of the printer to meet the desired printing result.