The types of printed circuit boards are becoming more and diverse. Their functions are also becoming more and complete. Among these, RF printed-circuit boards are rapidly growing, and their applications are wide. This article will help you explore the mysteries surrounding RF PCB.

What Is Radio Frequency?

RF is the abbreviation for radio frequency, which refers to the range of frequencies that electromagnetic waves can be transmitted into space. These range from 300kHz up to 300GHz. Radiofrequency is the abbreviation for a high-frequency, alternating electromagnetic wave. Low-frequency currents are alternating voltages that change less than 1,000 times a second, while high-frequency is alternating voltages that change more than 10,000 changes per second. Radio frequency is a high-frequency alternating current.

In electronic theory, electromagnetic waves are the electromagnetic fields created by an alternating current flowing through a conductor.

The Earth's surface absorbs electromagnetic waves with frequencies below 100kHz and they cannot be transmitted effectively. When the frequency of electromagnetic waves is greater than 100kHz they can be spread out in the air, and transmit signals for long distances. Radio frequencies are high-frequency electromagnetic waves that have the ability to transmit signals over long distances.

What Is the Purpose of Radio Frequency?

RF is used to wirelessly transmit information. Radio frequency (high-frequency electromagnetic waves) is used to communicate over long distances. It can be transmitted over long distances by propagating in the air, reflecting through the ionosphere on the outer edge. The radio frequency technology is used widely in wireless communication, radar systems and medical equipment.

Radio Frequency Characteristics

The characteristics of radio-frequency (RF), as defined by the IEEE, are:

High Frequency: Radio frequency waves have a high frequency and can transmit more information.

Long-range transmission ability: Radio frequency waves have a longer transmission range than electromagnetic waves. This makes them suitable for communication devices with a large range.

Strong penetrating: The radio frequency waves can penetrate walls, mountains and forests. They can transmit a complete range of signals, including communication signals.

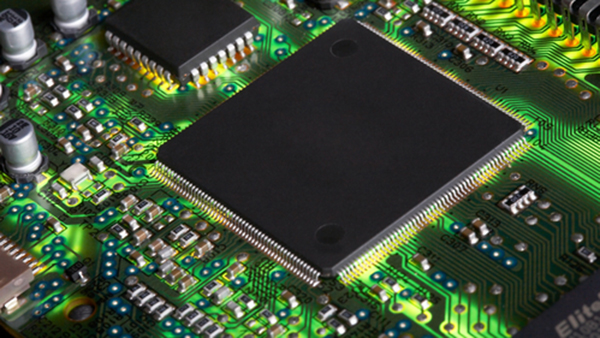

What Is a RF PCB?

RF-printed boards are a type of high-frequency board. A high-frequency board that uses radio frequency technology is called an RF board. A RF board is a high-speed circuit that operates at frequencies of 100mhz or higher, usually between 500mhz-2ghz. A PCB is microwave if the frequency exceeds 2ghz.

The difference is in frequency. There are some differences between circuit boards.

Radio frequency circuits may be designed with lumped parameters or mixed parameters.

The size of the microwave circuit is nearly the same as its wavelength. Therefore, it must be designed with distributed parameter components.

Characteristics of RF Printed Circuit Boards

RF printed circuit boards are manufactured with more complex mechanical equipment such as laser direct imaging, plasma etching machines, etc. The RF technology and precision equipment used in the manufacture of RF circuits allows them to have the following features:

1) Strong Temperature Control Capabilities

Thermal conductivity is lower in RF-printed boards than it is for ordinary printed circuits made from FR-4. This means that they can be used under high temperatures for a very long time.

2) High Frequency

Their electromagnetic wave frequency is greater than other circuit boards. This allows for a longer signal transmission range and a larger area. Wireless communication equipment can transmit information faster.

3) Three-Dimensional Stability

The RF PCB substrate material is polytetrafluoroethylene (PTFE), which has a lower coefficient of thermal expansion (CTE) than traditional FR4. The RF board is therefore more stable at high temperatures.

Mixing PTFE and FR4 materials when designing a board can reduce the size of the board. FR4 can reduce production costs because it is cheaper.

What Materials Are Needed for RF Circuit Board?

Material selection is based on a number of factors, including dielectric constant (DK), coefficients of thermal expansion (CTE), manufacturing, passive intermodulation, cost, etc. It is important to evaluate and consider the project from many angles to ensure that it meets the design requirements.

1) Polytetrafluoroethylene (PTFE)

The PTFE material is used in the design of RF components because it has a low thermal expansion coefficient and a high dielectric constant. It also performs as well as Teflon or Rogers.

2) FR-4

Flame retardant is referred to as Fr-. FR -4, also known as FR-4, is one of the more common PCB materials. It is cheaper than PTFE. It is suitable for electronic devices. The high thermal expansion coefficient will limit FR-4's use in higher frequency RF applications.

3) RO4000 Series

It is a series of composite materials made from PTFE and glass fiber. Low Dk, low loss, suitable to high-frequency circuit designs, reduces passive intermodulation performance (PIM), and provides better stability.

4) RO3000 Series

The RO3000 series, like the RO4000, is a PTFE-based product, but it has different dielectric constants, and other properties that are suitable for different RF design. The models include RO3003, RO3006, and RO3010 high frequency laminates.

5) Aluminum-Based Printed Electronic Circuit Boards

This circuit board is suitable for radio frequency fields with high power. It uses aluminum as a substrate, which improves heat dissipation.

6) Ceramics Metallized

Some devices that operate at microwave and very high frequencies use this material. Metalized ceramic PCBs have excellent stability and lower dielectric losses.

Applications of RF Circuit Boards

1) Communication

The radiofrequency technology plays a significant role in wireless communication, including mobile communications, satellite, wireless broadcasting and radar.

2) Field of Electronic Radiofrequency Equipment

Radiofrequency technology is used in many electronic devices such as microwave ovens and radios.

3) Medical and Life Sciences

Radiofrequency technology has been widely used for many years in the medical and life sciences fields.

4) Electronic Games

In electronic games, radiofrequency technology is used for wireless microphones and controllers as well as near-field communication.

5) Aerospace

The use of radiofrequency technology in space exploration and artificial satellites, including orbit control, satellite communication, etc., is essential.

Radio frequency technology plays an important role in many industrial and scientific fields.

What Should You Consider When Designing RF PCBs?

When designing a circuit, there are a number of factors to take into consideration, including parameter settings, manufacturing cost, manufacturability etc. Parameter settings are important because they influence the performance of the board.

RF board design can help you achieve the highest performance circuit board.

1) Impedance Matching

Proper impedance matching is important to ensure efficient power transmission between components. This process is based on the consideration of line width, substrate material and routing configuration.

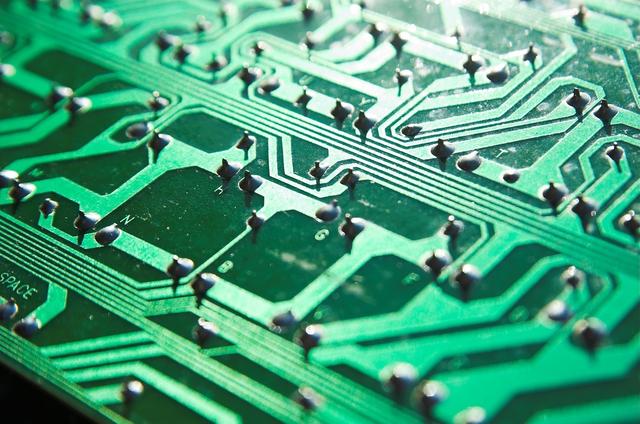

2) Cable Routing Design

The layout of the traces has a great impact on the signal transmission. It is easily damaged. To reduce losses and improve performance, it is best to use short and coplanar traces.

3) Through Hole Usage

This can lead to unintended capacitance, which can cause distortion of the signal. In the design of the vias, it is important to reduce them as much as possible. The hole size must be uniform and the vias for pins or pads should be specified.

4) Ground Planes, Vias

5) Decoupling of the Power Supply

Power supply decoupling can be used to reduce noise on RF circuit boards. Decoupling capacitors are a great way to eliminate power supply noise. It is important that the capacitors are placed carefully.

The RF components as well as the capacitors must be placed side by side.

Each capacitor must be equipped with a via

The capacitor that has the lowest power should be placed close to the power source and arranged in order of size.

RF PCB Manufacturing: Special Processes and Technologies

RF circuit boards are manufactured differently than traditional circuit boards. There are several key manufacturing processes that must be followed in order to maintain high-frequency circuit performance and stability.

1) Material Selection

It is important to choose the right material for high-frequency applications. Common materials include polytetrafluoroethylene (such as Teflon and RO4000 series materials ).

2) Imaging, Lamination, Etching

Laser imaging machines and plasma etching equipment are used to ensure that RF circuit boards are produced with the precision required. This ensures that the circuit accuracy meets design requirements.

3) Control Board Thickness

The thickness of the board is important for electrical stability, and must be uniform during PCB production.

RF Circuit Testing

1) Test for Impedance

Impedance matching tests are a necessity in the manufacturing process. They affect the signal loss. This test checks that the circuit impedance matches the impedance specified in the design. The time domain reflection (TDR), is the most common test.

2) Functional Loss Test

Loss characteristics should be tested within the power range of the RF PCB to ensure the quality of the signal is not compromised by excessive loss. Test methods that are commonly used include:

• Conversion of frequency

• Transmission Line Method

• Heat balance method

• The DC Power Measurement Method

3) Test for Environmental Adaptability

Test the circuit boards under different humidity and temperature conditions to determine their stability in different environments.

Future Trends

The RF PCB Market is growing rapidly, thanks to the Internet of Things (IoT), 5G communication, smart homes and other areas. This encourages further innovation and competition on the market.