1. It is the responsibility of engineers and technicians to accept new stencils and ensure that they are checked carefully in accordance with the standards set out by photolithography files, inspection reports and the supplier.

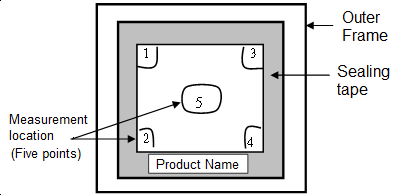

2. The stencils should be tension-tested before they are accepted and used in production. The test must meet the following requirements: Five test points are selected, of which four are located on each corner of the mesh cabinet. The midpoint between the center of stencils and the edge of stencils is used as the test.

When the size of the stencil is 55*65 it must not be lower than 40 Newtons/centimeter. For 42*52 it must not be below 35 Newtons/centimeter. The tension standard for SMT stencils must meet certain requirements during use: When the size of the stencil is 55*65 it cannot be lower than 30 Newtons/centimeter. For 42*52 it can't be less then 25 Newtons/centimeter. The maximum difference in tension test results must be kept within 10 Newtons/centimeter.

3. The stencils administrator is notified after the engineering staff has accepted the new stencils to apply the stencils labels. If the acceptance is not qualified, it must be sent back to the supplier.

4. It is the responsibility of the administrator to test the tension and record the results. Feedback should be provided to the customer as soon as possible if any problems are discovered.

5. In the production department, stencils will be numbered and registered uniformly and stored in their designated place on the stencil rack. To make it easier to distinguish, stencils from different customers are stored in distinct areas marked with clear markings.

Shenzhen SMT factory: Each compartment in the stencil frame is only able to accommodate one stencil. It must also be possible to access the stencils without any hindrance.