The likelihood of welding problems increasing as the size and integration of electronic components continue to shrink is also on the rise. It is important to identify high-quality joints, especially when printed boards are used in critical areas. Here are 13 common PCB weld problems to avoid.

This guide will help you to avoid welding problems during project implementation, or assess the quality of printed circuit boards assembled by third parties.

Ideal Welding Joint

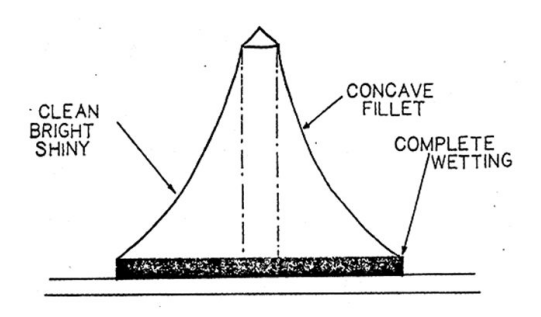

It is very helpful to use an image of a perfect welding joint as a guide when detecting defects. Ideal through-hole weld joints are like works of art.

Ideal Through-Hole Weld Joint

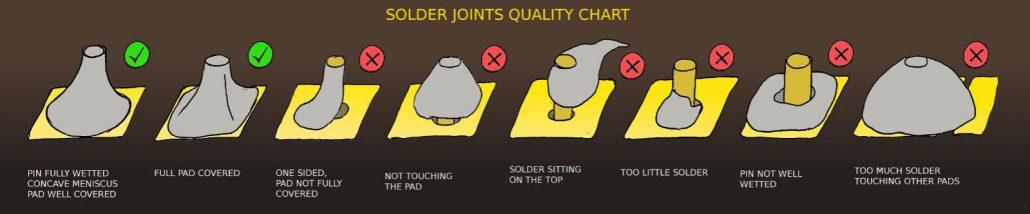

The ideal shape for a welding joint on a through hole component is a "recessed" corner, with an angle between 40 and 70 degrees to the horizontal plane, and a shiny, smooth concave surface. This shape is similar to that of the logo of the chocolate company "Hershey". The ideal shape of the welding joint can be achieved if the temperature of the welding iron is correct and the oxide layer is removed from the PCB contacts.

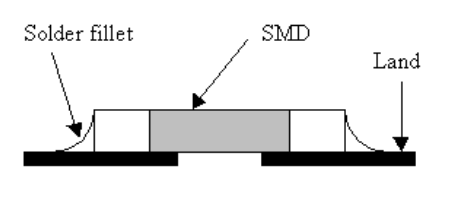

Ideal Surface Mounting Welding Joint

The corners of high-quality SMD joints are also recessed and smooth.

High-quality welding joints have these characteristics:

Good wettability

Concave rounded corner

Surfaces that are shiny and clean

Bad Welding Joints

Welding joints can fail for many reasons, including the fact that it tends to flow in the wrong direction.

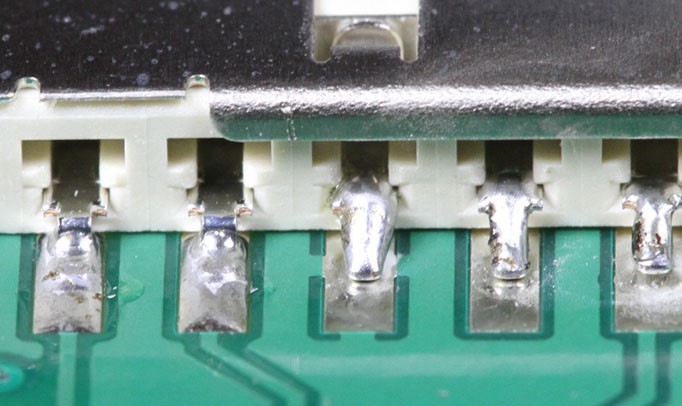

1. Welding Bridge

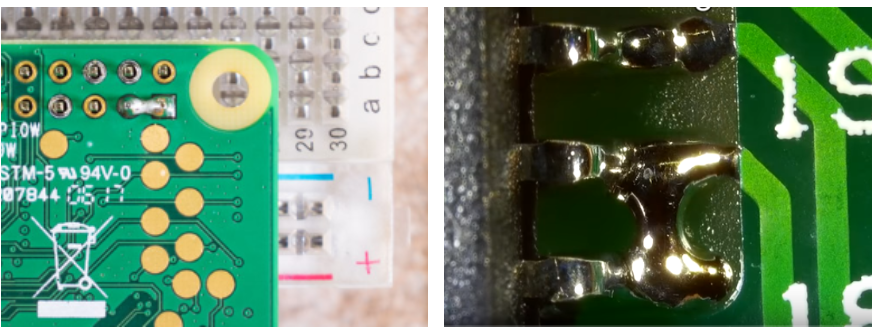

Welding bridging is one of the most common problems that are caused by miniaturized electronics. If two or more joints connect unexpectedly, either too much welding has been done or a wide or oversized welding tip is used. This results in an unexpected bond between the joints. It can be difficult to detect the welding joint bridge because it is so small. The component may burn if the welding bridge cannot be found quickly.

The following measures can be used to fix the problem of welding bridging: Heat the center area of the bridge with a welding iron, melt the welds, and then remove the iron carefully to destroy the bridge. You can remove excess welding from a large welding bridge by using a welding sucker.

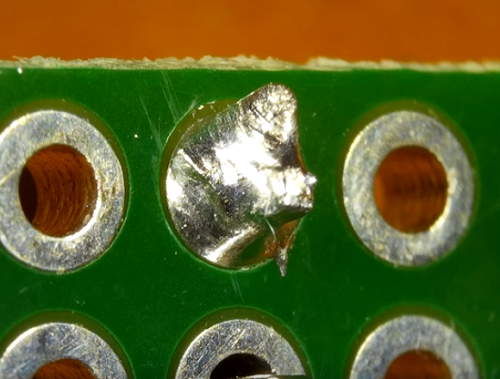

2. Too Much Welding

Excess welding can form a buildup that has a rounded look. Many beginners believe that welding more is better. While it does increase the amount of material that forms the joints, too much welding can make it difficult to determine the exact situation underneath the welding area. It can lead to the pin or pad being improperly wetted, increasing the likelihood of welding bridges. The principle of safety must be observed. In general, a small amount of welding will be enough to wet the pin and pad, while the concave surfaces can remain in optimum condition.

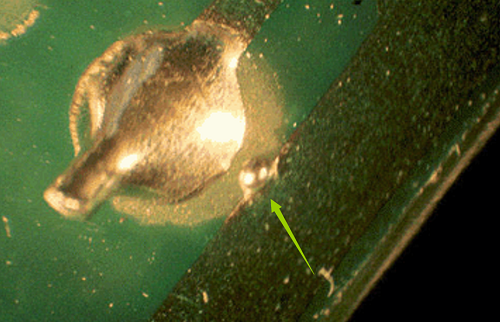

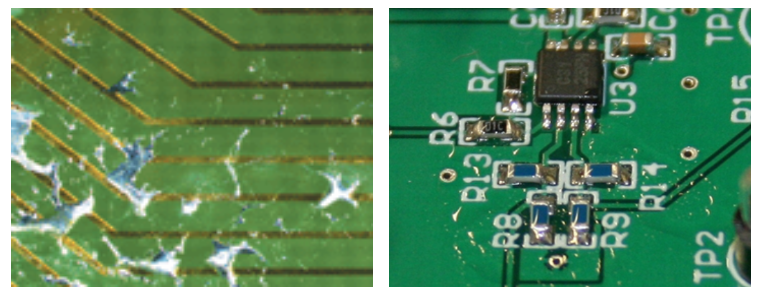

3. Welding Balls

Wave welding and reflowing are the most common methods of occurrence. These small welding balls can be found on the surface of the laminate, resist or conductor. There are many factors that can cause welding balls to form.

Factors such as improper printing of welding paste, incorrect reflow temperature, poor PCB design or use of oxidized components.

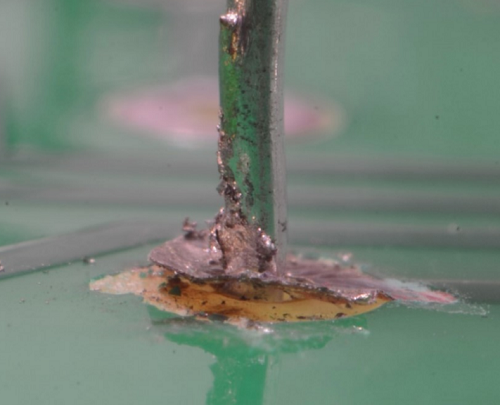

4. Cold Joints

Insufficient heat is the most common cause of a dull, lumpy or pitted welding joint. It can be due to a number of different factors. The welding iron may not have been given enough time for heating up or the temperature of the welding is too low to melt the used welding (for instance, lead-free welds have a higher melting level). This problem can also be caused by the design of pads and traces. If the pad is connected directly to the plane of the ground without taking heat dissipation into consideration, then the heat from the welding iron can quickly reach the plane. A stubborn weld joint may indicate a defective design. If the corrective measures aren't taken,

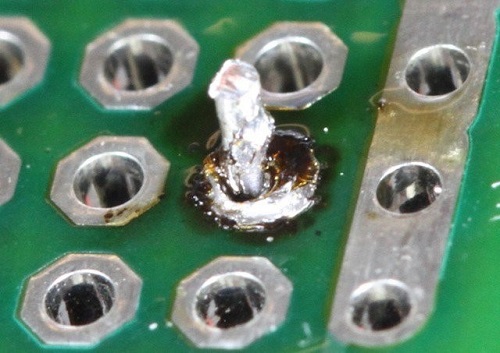

5. Joint Overheating

Too much heat can also cause headaches. The iron temperature can be set too high, or there may be an oxide layer covering the lead and pad surface. This prevents heat transfer to the joint and causes overheating. In some cases, improper heating can lead to damage. We hope that it is only flux burnout. However, in other cases, the pad may fall off, causing serious damage to the board. It is important to use the correct welding iron temperature to avoid problems. Also, using flux to clean dirty joints and pads will help to prevent such problems.

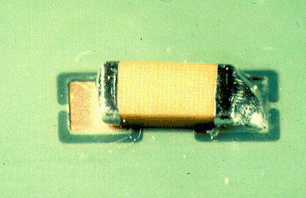

6. Monument

Tombstone defects are typically caused by surface-mounted components such as capacitors or resistors with the one end raised off the pad. The welding should be evenly adhered to both pads, and the wetting process should begin. If the wetting process is not properly worked out on one of pads, the component may tilt to one side, giving it a tombstone appearance. Tombstone is a problem that can arise during reflow welds if the paste used on one pad melts faster than the paste used on the other. This problem can be caused by, for example, an inadequate thermal design of the traces that connect the pads or an uneven thickness. Wave welding can cause large component assemblies to be pushed into a tombstone shape by the wave. When designing boards for wave-welding, layout engineers should consider the direction of a welding wave.

7. The Holes Are Not Adequately Wetted

Joints that are not completely wetted appear weak and do not form a strong connection with the board. The ideal welding would cover all pins and pads without any gaps. The pins or pads are not sufficiently wetted when the heat is not applied simultaneously to both. The board itself can be contaminated. This problem can be solved by cleaning the board thoroughly and making sure that the pins and pads are heated evenly.

8. Surface Mount: Inadequate Wetting

Only the leads are heated, so there is no welding on the pads. The leads are only heated so there is no welding on the pads. Surface mount devices are also susceptible to poor wetting. The three pins on a surface-mount device do not have good wetting. The pins, and not the pads, are being heated. This is why the weldings do not flow to the pads. This defect can be fixed by heating the pads using the tip of the welder and adding more welding until it flows and merges the existing welding on the pins.

9. Welding Ski

Welding funneling is the term used to describe a welding joint that has not been adequately soaked by welding. The surface mount pad is left exposed when the welding does not cover it. This phenomenon can be caused either by errors in the manufacturing or design process. It may be caused by inconsistent pad sizes, or the manufacturer using a wrong wave height between board and welding wave.

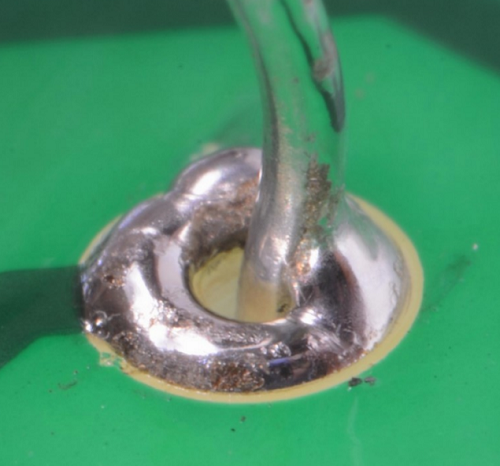

10. Pad Shedding

The pads could have separated from the PCB due to heat or force applied to the existing weld joints. These pads can be difficult to handle as they are fragile and easily tear from the wire pathway. It is important to try to attach the pad back to the board prior to welding.

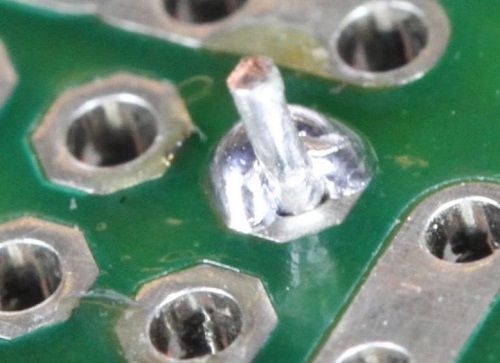

11. Welding Starvation

Insufficient welding can lead to a weak electrical connection. The leads could not be heated enough, which would result in a bad connection. The joint may still work temporarily, even though it has electrical contact. Over time, however, the cracks in the joint will grow, weakening it. Repairing an insufficiently-welded joint is easy. The joint should be reheated and the welding added.

12. Welding Splatter/Webbing

The welding mask is covered with small amounts of welding that splatter in an irregular pattern. This irregular pattern of threads is usually caused by a lack of flux or contamination on the board's surface when wave welding. These contaminants can lead to short circuit problems.

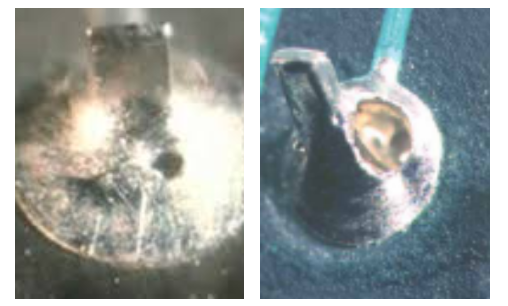

13. Pinholes and Blowholes

Yt-electronic: Pore and pinhole defects are easy to detect because they appear in the weld joint. The term "pore" is used to indicate the size of a hole. "Pore" indicates larger holes. Wave welding is not the cause of pinholes or pores. Their formation also has nothing to do wth manual welding. Heat transforms moisture on the PCB into gas during the welding process. When the welding join solidifies, if the gas is not fully expelled while the welding process is still liquid, it can cause voids. To avoid this problem, you can bake or heat the circuit board in order to remove moisture. You can also ensure that the copper plating is at least 25 microns thick.