A Complete Guide to Automotive Electrical Connectors

Learn all about automotive electrical connectors, wire terminals, and connector types used in modern vehicles. Stay safe and make smart upgrades.

Table of Content

Let’s face it, cars aren’t getting simpler. Open the hood of any modern vehicle and it’s not long before you’re staring at a spaghetti mess of wires, fuses, and little plastic clips that seem designed to confuse you. But here’s the thing: behind every beep, blink, and engine rev, there’s one underrated hero, automotive electrical connectors.

These connectors are everywhere. They keep your headlights from flickering. They help your sensors talk to your engine control unit. They make sure your car stereo electrical connectors stay locked in when you’re blasting music over speed bumps. If you’ve got wires, you’ve got connectors. And when those connectors fail, all hell breaks loose.

Whether you’re installing new fog lights, upgrading your dash cam, or just trying to figure out why your indicators stopped working, understanding automotive wire connectors and car electrical connectors is step one. And knowing which ones to buy, or avoid, could save you hours of frustration, not to mention money.

1. What Are Automotive Electrical Connectors?

So, what exactly are automotive electrical connectors? Think of them as your car’s handshake system. Every time two wires need to exchange power or information, a connector steps in to make the deal happen. It’s like plug-and-play, but made to handle heat, vibration, grime, and the occasional roadside emergency.

More specifically, these automotive wire connectors join wires or components together in a way that allows the current to flow without interruption. From the engine control unit (ECU) to your heated seats, they’re used throughout the vehicle. And we’re not talking just one or two, you’re looking at hundreds of car connectors packed into the average car.

Take this real example: your check engine light turns on. You scan for codes, nothing. A few wiggles behind the fuse box and the light disappears. Odds are, a faulty automotive wire terminal was the real culprit. Over time, even small amounts of moisture or movement can compromise the connection, and with it, the entire system.

That’s why reliable automotive wire and connectors aren’t just a preference, they’re a necessity. If one car electrical connector fails, your entire wiring setup could act up in weird, unpredictable ways.

2. Automotive Electrical Connectors Types

Now that you know what automotive electrical connectors do, let’s talk about the types. Because not all connectors are created equal, and using the wrong one can lead to overheating, poor conductivity, or total failure.

2.1 Sealed vs. Unsealed Connectors

- Sealed automotive electrical connectorsare built tough. They’re water-resistant, dustproof, and made for under-hood or off-road applications where dirt and heat are constant threats. If you’re dealing with engine bay connections or external lighting, these are your go-to.

- Unsealed connectors, on the other hand, are fine for interior jobs, like car stereo electrical connectors or cabin sensors. They’re easier to install and cheaper, but keep them away from moisture.

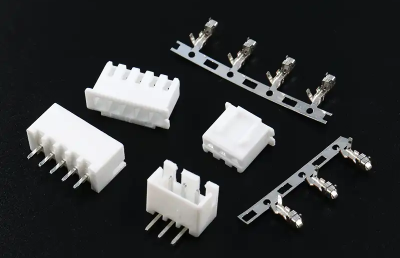

2.2 Styles of Connectors You’ll Actually Use

- Blade terminals: Probably the most common. Flat, push-fit designs used for switches, lighting, and relays.

- Bullet connectors: Round male/female setups for fast disconnects. A favourite in older cars and quick fixes.

- Butt connectors: These crimp two wires together in-line. Ideal for repairs and extensions.

- Ring terminals: Great for grounding. Fit perfectly around screws or bolts, often seen in battery connections.

2.3 OEM-Specific vs. Universal Options

- OEM-specific connectorsmatch the original parts in your car. They offer a tight fit and reliable performance, especially for mission-critical components.

- Universal connectors, like auto wire connectors or car wires connectors, are more flexible and cheaper but might require extra fiddling to fit properly.

Understanding the difference between automotive electrical terminals, auto electrical connectors, and various automotive wire connectors isn’t just useful, it’s essential if you’re doing any kind of wiring work. Use the wrong terminal, and that fancy new fog light might short out the moment it rains.

3. Choosing the Right Connector for the Job

So, you’ve figured out what type of automotive electrical connector you need. Great. But the next question is just as important: is it the right connector for your car?

Not all connectors are created equal. What works for a Ford pickup might fry the circuits in a Toyota hybrid. Before you crimp or plug in anything, you’ve got to think about a few key factors.

1) Start with Compatibility

Is your car from the nineties? Is it loaded with digital sensors? Different systems mean different automotive electrical connectors. Your ABS sensor won’t use the same car connector as your backup camera. Double-check specs. Triple-check fit.

If you’re replacing factory wiring, OEM-style car electrical connectors are your safest bet. But if you’re working on a custom job, like retrofitting LED strips or installing a new amp, auto wire connectors and universal car wires connectors might do the trick, just make sure they’re rated for automotive use.

2) Voltage and Current Matter, A Lot

Let’s say you’re wiring up some fog lights. You find a bag of leftover automotive wire terminals in your toolbox. Easy win? Not necessarily. If those terminals aren’t rated for the amps your lights draw, you’re asking for melted plastic, or worse.

Always check the amperage and voltage rating of any automotive electrical pins you use. Underrated gear doesn’t just fail, it fails dangerously.

3) Don’t Ignore the Environment

Where’s this connector going? Under the hood? Near a speaker? Inside the tailgate?

If it’s going to be near heat, oil, vibration, or moisture, you’ll want sealed auto electrical connectors. For cabin installs, like car stereo electrical connectors, unsealed options usually hold up just fine, and they’re easier to work with.

4. Common Connector Applications in Cars

Let’s take a step back. You might be wondering: why so much fuss over automotive electrical connectors? Because they’re tucked into nearly every corner of your vehicle. Knowing where and how they’re used can save you from hours of troubleshooting, or a costly repair bill.

- Engine Management Systems

Modern engines rely on a complex web of sensors and modules. Airflow meters, oxygen sensors, throttle position sensors, all of them talk to the ECU through automotive wire connectors. These connections with the automotive wire connectors must be durable, waterproof, and heat-resistant. A single faulty auto electrical connector can trigger limp mode or prevent the car from starting entirely.

- Lighting Circuits

Whether it’s headlights, brake lights, or signal indicators, all exterior lighting systems depend on reliable car electrical connectors. These automotive wire connectors often pass through high-flex areas like trunk lids or bumpers, which means you need sealed automotive electrical terminals to prevent moisture damage. If your tail lights flicker when you close the trunk, check the auto wire connectors or car wires connectors first.

- Audio and Infotainment

Messing with your car stereo? That’s where car stereo electrical connectors and auto electrical connector types come in. Today’s systems integrate with steering wheel controls, GPS, backup cameras, and more. A misplaced wire or mismatched pinout can knock out half your setup. Thankfully, most audio upgrades rely on standardized automotive wire terminals that make DIY installs manageable, even for beginners.

- EV and Battery Systems

Electric vehicles use high-voltage wiring, which requires robust automotive electrical connectors with added insulation, secure locking mechanisms, and reliable sealing. There’s no room for error here. Using the wrong connector, or guessing instead of checking a diagram, can lead to serious safety risks. Always follow manufacturer guidelines when dealing with EV wiring.

5. How to Install and Crimp Automotive Connectors Properly

Alright, you’ve got the parts. Now let’s not mess it up. Because even the best automotive wire connectors won’t save you from a bad crimp job.

Step 1: Strip Your Wire, Clean and Precise

Use a proper wire stripper. Don’t just hack away with scissors or your teeth (yes, we’ve seen it). Leave about ¼ inch of exposed copper. Too much, and you’ll get shorts. Too little, and the crimp won’t hold. Automotive wire connectors are relatively delicate work.

Step 2: Choose the Right Connector

Double-check size and type. Using automotive electrical terminals? Match the wire gauge. For auto electrical terminals, make sure you’ve got the proper seal if it’s going under the hood.

Step 3: Crimp It Like You Mean It

Use a ratcheting crimper, not pliers. Squeeze until you hear that click. You want a solid mechanical bond, not a squishy mess that falls apart at the first bump.

Step 4: Test It

Before wrapping things up, give the connector a gentle tug. If it slides off, do it again. If you’re using car wires connectors near moving parts, add heat-shrink tubing or electrical tape to protect the joint.

Step 5: Secure and Route Properly

Use zip ties, loom tubing, or clips to keep your wires from moving around. Loose wires flex. Flexing wires fail. Every clean install reduces the chance of needing to redo your work later.

6. Troubleshooting Electrical Connector Problems

Even with top-notch automotive electrical connectors, things go wrong. Vibration, heat, water, time, your car throws all of it at these little plastic and metal parts. Knowing how to spot issues early can save you from breakdowns or electrical gremlins later.

Symptom 1: Loose Connections

One minute your turn signal works, the next it’s out. Sound familiar? A wobbly car connector might be to blame. This usually happens when clips wear out or wires shift from heat cycles. A quick visual check and a wiggle test can reveal a lot. If the wire feels loose inside the automotive wire connector, it probably is.

Symptom 2: Corrosion and Rust

Moisture is public enemy number one for car wires connectors and automotive electrical terminals. If you see green or white residue around a connector, that’s corrosion. And while cleaning it with contact cleaner might help temporarily, you’ll want to replace it with a sealed auto electrical connector to avoid repeat issues. You can’t have automotive wire connectors corrode.

Symptom 3: Short Circuits and Cut Power

A common mistake: assuming the fuse is the problem. But if you’ve blown the same fuse three times, look at the wiring. Frayed insulation or bent pins in the automotive electrical connectors can short out a circuit and kill power.

Grab a multimeter. Check continuity between the wires inside the suspect connector. If resistance is too high, or worse, infinite, you’ve likely found your culprit.

7. Automotive Wiring Harness Connectors and Terminals

Here’s the part most DIYers overlook: automotive wiring harness connectors and terminals aren’t just another piece of the puzzle. They’re the backbone of your vehicle’s entire electrical system.

7.1 What is a Wiring Harness?

Imagine trying to run 150 separate wires through your car’s engine bay without organization. It’d be chaos. A wiring harness bundles all those wires together and routes them logically, often with dozens of automotive electrical connectors attached.

When one harness connector fails, you might lose your headlights and your dashboard and your power mirrors. It’s all connected, literally.

7.2 Replacing vs. Repairing

Sometimes, replacing the entire harness is the smart move, like when your car’s been in a flood or fire. But in most cases, you can swap just the faulty automotive electrical terminals or damaged auto electrical connectors. It’s cheaper, faster, and doesn’t require tearing apart your car’s entire interior.

Just be sure your new connectors match the originals in pin count, layout, and rating. And if you’re splicing, use proper automotive wire terminals, not hardware store junk.

8. Connectors FAQs

9. Summary

Let’s be real: most car problems don’t start with something big. It’s the small stuff that gets overlooked, like a corroded automotive electrical connector behind your headlight or a loose automotive wire terminal rattling under the dash.

By understanding your car’s electrical setup, choosing the right connector types, and using quality auto wire connectors, you avoid endless trial-and-error repairs. And you don’t have to be a pro. You just need to know where to look, and what not to ignore.

So next time something electrical acts up, don’t just blame the fuse. Check the connectors. They’re the unsung heroes keeping your car’s systems humming.

And if you’re upgrading, don’t skimp. Use sealed automotive electrical connectors where it counts. Crimp properly. Test everything. Your future self will thank you.

related Posts

Contact us

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Teams: alek_youte

Email: sales@yt-electronic.com