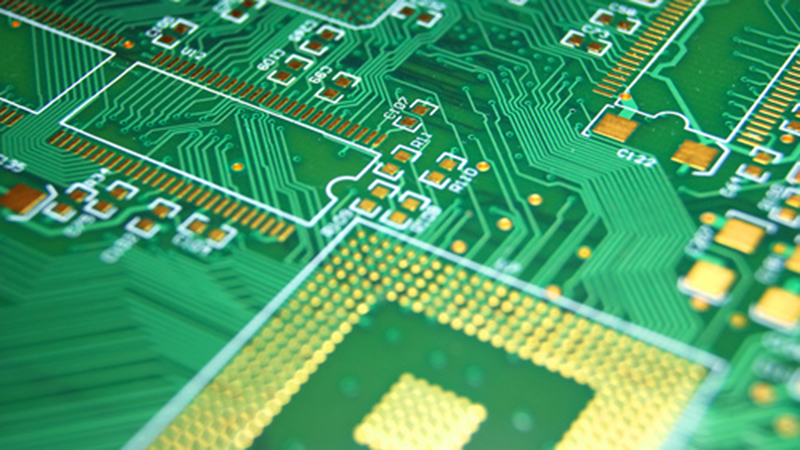

Mini 3.5 Inch Industrial Control Motherboards with SMD Processing

As a professional manufacturer of SMT components, pcbandasembly can manufacture high-end chip products including mini industrial motherboards.

– The Mini 3.5 motherboards were produced on an SMT machine, right?

– Yes.

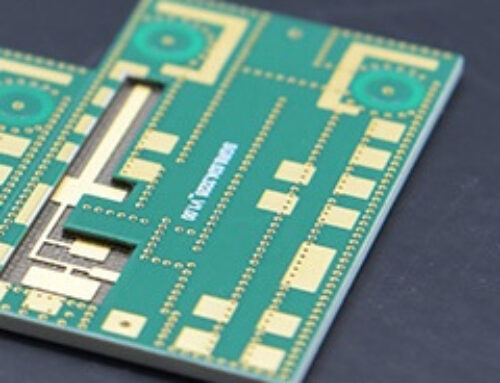

The operation principle for a professional SMT (Surface Mount Technology), component manufacturer is

simple: electronic components like capacitors and resistors, are mounted on the circuit board using an

SMT machine. A reflow-soldering process completes the assembly. The SMT chip technology is best suited

to electronic products with high precision and integration, such as mobile phone motherboards and tablet

computers. These devices are produced using advanced chip processing technologies. This production

method, collectively known as patch processing, allows for the systematic arrangement of resistors and

capacitors.

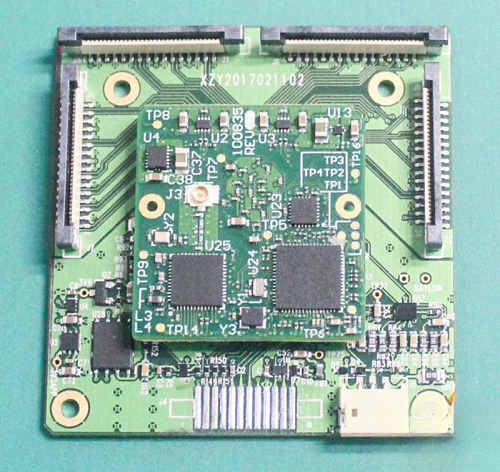

Two primary production technologies exist:

1. SMT (component mounting using a mounter, followed by reflow-soldering);

2. DIP (through-hole inserting requiring wave soldering after insertion). Pure DIP

processes remain relatively rare, but they are still used in the production of outdoor display lamps

boards. In most cases, the products are first processed via SMT and then transitioned to DIP. These

methods are often used together.

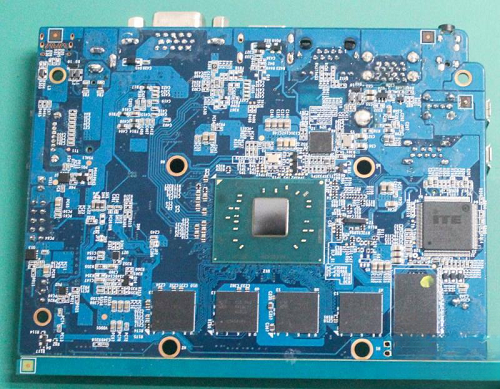

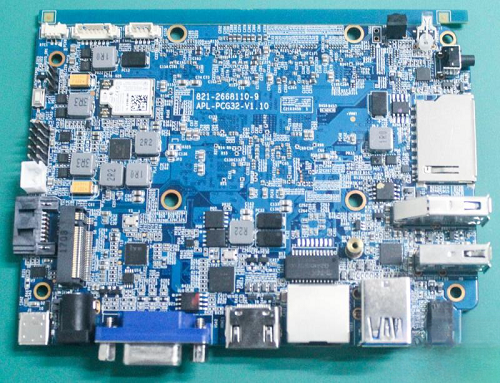

These mini industrial motherboards are characterized by the high chip value. They also feature embedded

CPUs designed specifically for industrial control applications.

The double-sided patch is the hallmark of superior-quality processing products. The front of the product

features embedded chip-patch technology.