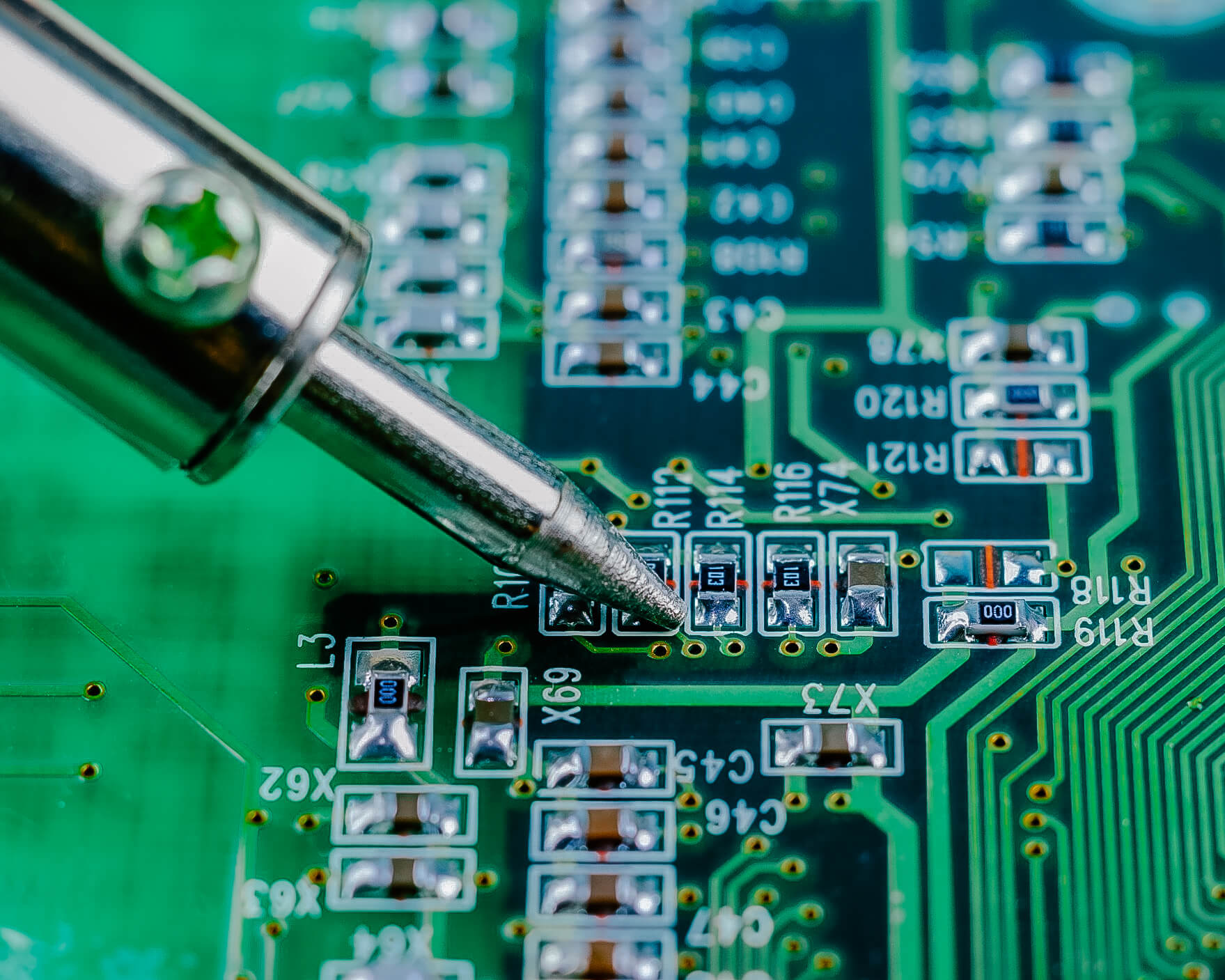

IQC Incoming Material Inspection

This article introduces the purpose, scope, and steps of incoming material inspection from Shenzhen PCBA manufacturing factory.

Inspection Purpose: To eliminate material defects to avoid adverse conditions in

production, thus avoiding the delivery deadline.

1. Purpose

To ensure that the product meets the customer’s requirements and to ensure smooth production.

2. Application

This applies to all processes that are subject to quality control inspections.

3. Organisation and Responsibilities

(1) IPQC: confirmation of the first piece, inspection process, evaluation of quality,

guidance in operation, tracking and abnormal feedback, and recording inspection results.

1).First-piece confirmation: refers the confirmation of quality and production process

before mass production in order to prevent batch defects.

2).Self inspection operation: the operator checks the quality of the final product

according to the instructions.

3).Mutual Inspection Operation: Refers to the operator who checks the quality of a

product produced by a previous process.

(2) QA: Random inspection and complete inspection of finished products on the

production line.

(3) QE: develop or revise inspection standards for products, analyze process and

customer quality anomalies, track anomalies, and provide operation instructions.

(4) Production Department: organize production according to orders; make first-pieces

of products; conduct independent and reciprocal inspections; handle quality anomalies and rework

operations. Handle defective products. Apply for special purchases.