What Are the Advantages of Automating PCBA?

This article introduces seven benefits of PCB assembly and PCBA manufacturing automation, including cost savings, reduced errors, and fast production, etc.

1. Discounts on Price

Saving money can be a benefit of automated PCBA production. Assembling electronic circuits prior to

manufacturing. Surface mount technology manufacturers often rely on proprietary technologies. To reduce

glitches, lags and other problems. The designer of the printed circuit boards (PCBs) can correct any

design errors at this stage. The final product will not have any problems. Projects can be delayed by

errors such as incorrect footprints or missing polarity marks. The automated machines allow for a

reduction in the number of workers needed to complete a production. These reductions may lower the cost

for manufacturers to produce PCBA.

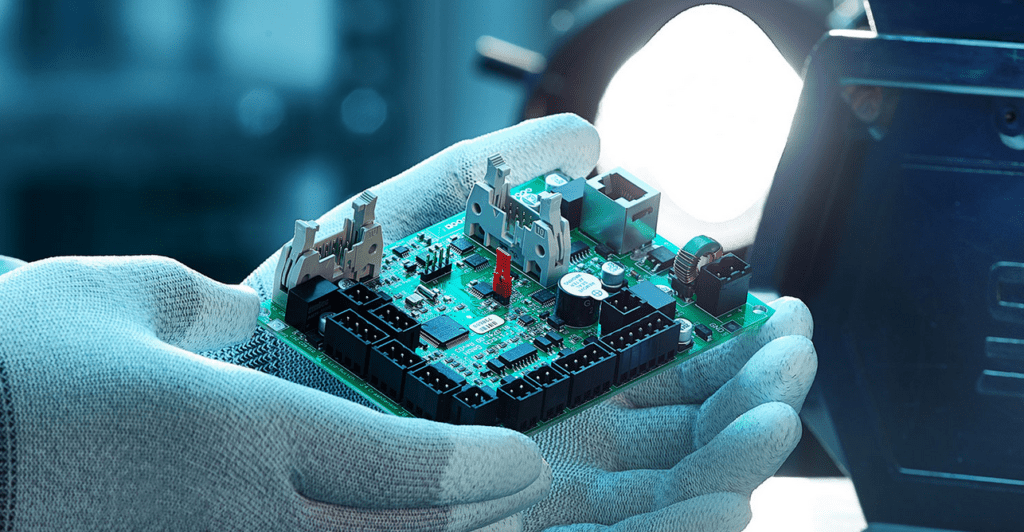

2. It Is Less Likely that a Human Error will Occur

When assembling circuits, it is important to pay attention to all the details. As products and parts get

smaller, this becomes more important. When human interaction is needed, the error rate increases.

Automation makes it less likely that errors will occur. Automation speeds up production and saves money.

Automation also reduces the chance of error.

The PCBA process can be challenging and tricky. Assembly of the circuit boards requires high precision.

Circuit boards and components are becoming smaller. Soldering components together requires care to

prevent errors. Humans and machines both make mistakes. Machines are less likely to make errors when

performing routine tasks or delicate ones. Automated systems are more reliable and efficient than manual

labor in these circumstances. Summary: Machines used with precise settings can reduce the chance of

errors.

3. Fast Product Production

The longer it takes to assemble manually, the more impact this has on the time needed to create a

product. Automation allows software development to be faster. You can do this because you can perform

other operations simultaneously. You can also find out the delivery date for the circuit board.

Automatic machines are more accurate and reliable than manual assembly because they perform the same

operation every time. You can be assured of a high-quality product by using an assembly service, as

automation maintains the sameness of every circuit board produced.

4. Consistency

Consistency is a problem with manual circuit boards due to their inherent error range. Automation

ensures reliability and consistency.

5. Great for Mass Production.

Automation reduces both production costs and time. Standards will still be met with mass production

because reliability is already present.

6. New Products Can Be Brought to Market Faster

The circuit board determines the timeframe for manual assembly by PCBA factories. It may not be

worthwhile to spend time manually making PCBs when other tasks are running in parallel. Outsourcing PCBA

assembly to a company using automated equipment will ensure that your boards arrive in perfect condition

and that multiple steps are completed quickly and easily. You will save time and money.

7. Customization to a Higher Degree

The increased flexibility of production due to automation allows for the customization of products.

Often, electronic products are mass-produced according to the same standards. Smart industry is expected

change this.

This enhanced adaptability will increase the speed with which OEMs are able to create prototypes and, in

turn, new product designs.