What Are the Different Types of PCB Surface Treatments?

Yt-electronic helps everyone understand the surface technology on printed circuit boards and compare various PCB surface treatment processes.

PCB innovation has also altered significantly

with the rapid growth of digital information technology. The need for modern product technology is

increasing. Some motherboards, such as those in computers and smartphones, use gold or copper. This

makes the benefits and drawbacks of motherboards more apparent.

Yt-electronic is a tool that helps everyone understand the innovation in printed circuit board surface

treatments. It compares benefits and disadvantages of various PCB surface treatment methods and the

appropriate circumstances.

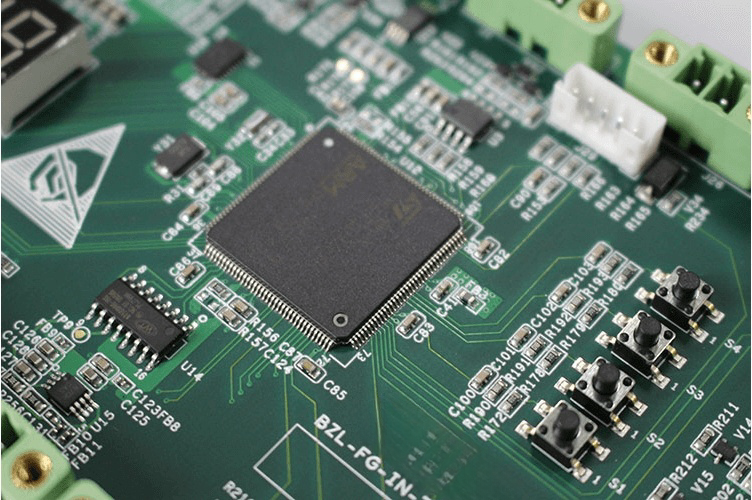

PCB refines the look of the board to have 3 main colors: light red, silver and gold. In terms of price,

gold is the most expensive color, followed by silver and light red. The look of the product will show if

the edges have been reduced. Circuit cards are made of pure copper and described as bare board.

1. An advantage of copper board bare is its low cost, flat surface, and weldability

without oxidation. Be careful to not be affected by acid or temperature. After being exposed to air for

a period of time, copper is easily oxidized.

2. Gold on the immersion board is gold. The cost of a thin layer of conductor can be

10% of the total circuit card. It is difficult to oxidize after immersion in gold treatment. It can also

be stored for a longer time and has a smoother finish. It can be used to weld some pins with fine gaps

and tools that have smaller solder joints. The welding power is not very strong and its cost is high.

3. Silver is the color of the circuit card that sprays tin. The tin is sprayed on the

copper circuit. Although it is useful for welding, its call integrity cannot match that of gold. If used

for an extended period of time, it is easy to oxidize or rust. This can lead to poor contact. The

circuit boards for some small electronic devices are often made of this material, which is inexpensive.

4. The OSP process board in the SMT manufacturing plant is also called the natural

change movie. It is cheaper than tin spraying because it’s a natural compound and not steel.

This method is similar to the bare copper sheet welding. Surface treatment can also be done on a

motherboard that has been terminated, but they will quickly become affected by humidity and acid.

Surface area treatment is required if the storage period exceeds 3 months. OSP is an insulating layer.

The test point must be soldered with paste in order to remove the OSP shielding layer.