What Are the Most Common Types of PCBA Substrates?

When we are encountering digital products, the PCBA board is an extremely integral part.This post explains the common types and requirements of PCBA substrates.

The PCBA board plays a vital role in

digital products. There are many different types of board, with a variety of features and applications.

This article explains PCBA substrates and their common requirements.

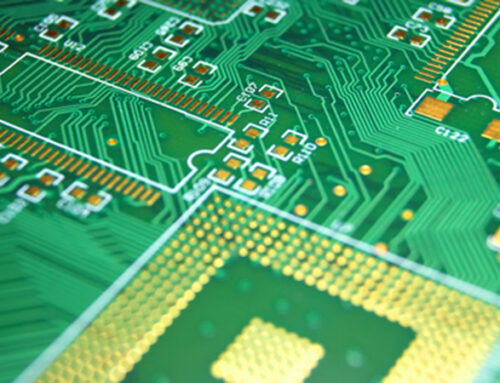

1.FR4 Substrate

The FR4 substrate is the most common veneer used in PCBA plants. It is a fiberglass-reinforced plastic

material frequently made use of in high-frequency and high-speed digital circuits. FR4 substrate is used

extensively in the production and design of PCBs because it has high temperature resistance and

mechanical strength. Its insulation is also outstanding, and it can usually meet the need for high

reliability.

FR4 boards of different densities can be used for various industries. The thicker the FR4 sheet, the

stronger it is mechanically, and therefore, more suitable for electrical residential or commercial

properties.

2.Light Weight Aluminum Substrate

Aluminum substratum is used in PCBA

manufacturing and it has many characteristics, including corrosion resistance, warmth

dissipation (and heat transfer), low cost, easy processing, etc. The aluminum substrate is used for LED

illumination, high-power, high-frequency, and other circuit boards. The LED lighting circuit board is

the most common. Since the heat of LEDs is high, heat dissipation must be done to reduce the

temperature. Light weight aluminum substrates are excellent at this.

Density of aluminum substratum can be 1.0mm, 1.2mm, 1.5mm etc. Aluminum substratum can be a great choice

for a motherboard that has a high heat output. It will ensure the stability and long-term operation of

the board.

3.FR1 Substrate

PCBA manufacturers use FR1 as a substrate because it is cheaper than FR4, but its mechanical and

electrical properties are less robust. It is therefore only used in low-end PCB design and manufacture.

It is generally 1.2 mm thick, but can be 1.0 mm thick. The manufacturing cost of FR1 can be reduced for

customer, making it a more affordable option.

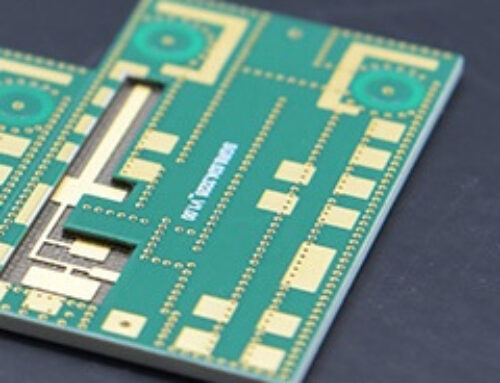

4. High-Frequency Board

A high-frequency plate has a special quality. It is ideal for high-frequency circuit design because it

transmits signals with outstanding qualities.

Summary

The selection of substrate is crucial in the PCBA production and design process. Substratum types are

available for various applications, and they should be selected according to the real needs. The FR4

board, which is the most common substrate, has both mechanical and electrical properties. Aluminum

substrates are excellent at dissipating heat. High-frequency boards are suitable for circuit cards that

need high-frequency transmission. However, their price is higher than other plates.

High-frequency circuit boards are used for RF circuits and microwave circuits. They can also be found in

antenna circuits and other circuit applications. High-frequency boards are typically thicker, between

0.2mm and 0.8mm. They have a higher price than other board types, but their digital performance and

market demand are excellent.