First Piece of SMT Assembly Quality Control

This article elaborates on the importance of first piece quality control in PCB SMT assembly from the perspectives of purpose, content, methods, and processes.

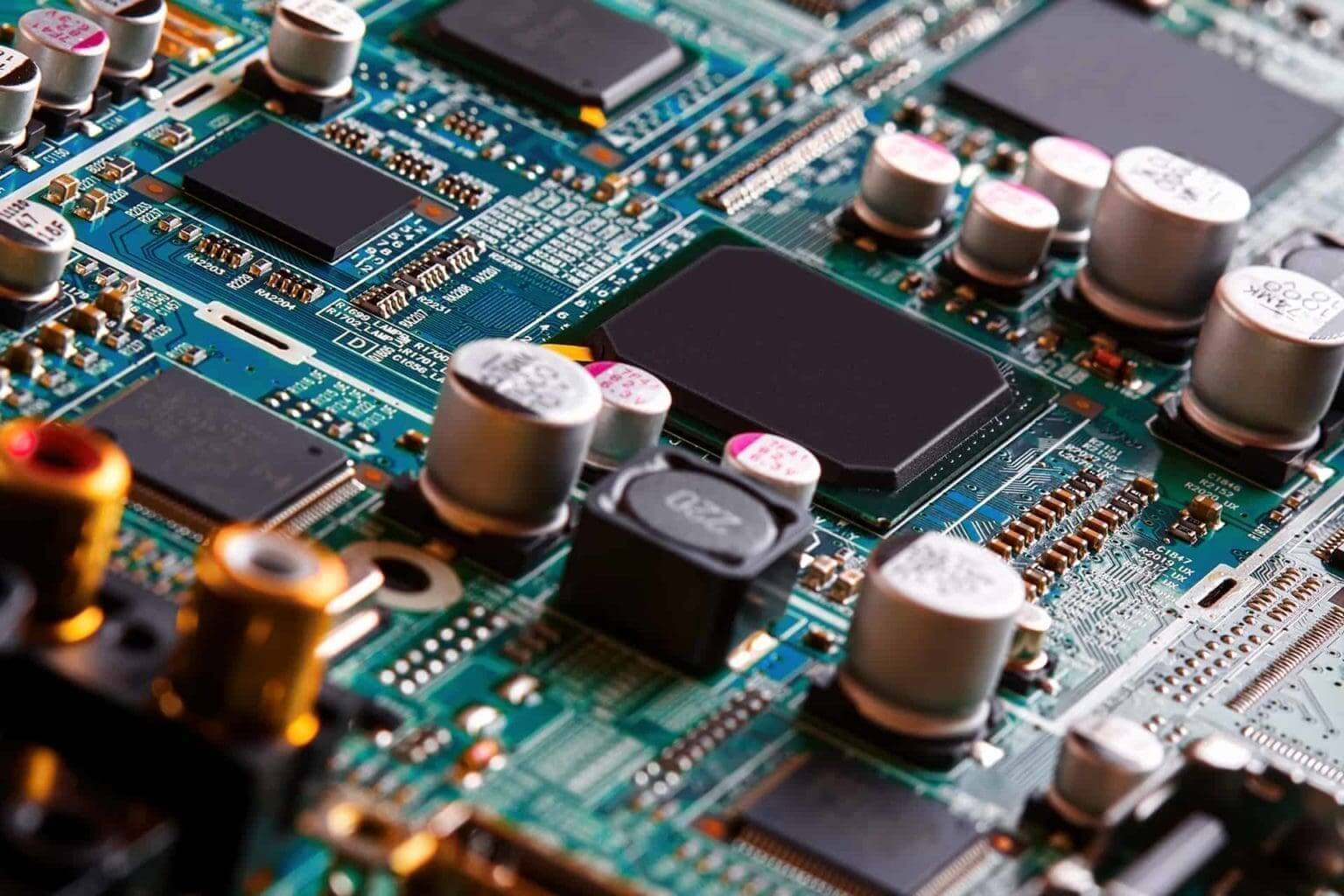

The SMT assembly process is an important part of the production of electronic products. Its quality

affects both the reliability and performance of the final product.

The control of first piece quality plays a major role in PCB SMT Patch Assembly quality control. It is also the key to ensure product

quality.

First Piece of Quality Control: What Is It For?

First-item quality assurance is designed to identify and eliminate defects in the product by performing

comprehensive testing and inspections on the first item. This will ensure that products meet the

customer’s requirements.

The First Piece of Quality Control Content

This content mainly includes:

1) Inspection of Materials

Make sure that the electronic component, board and solder paste you use meet all product requirements

2) Inspection of the Process

Make sure that the SMT placement machines, reflow Ovens, and other equipment are in good working order.

3) Inspection of Mounting Quality

Verify that the position, angle and polarity of the part meet the drawing requirements.

4) Welding Quality Inspection

To ensure that the solder joints meet the required requirements, check their shape, size and strength.

First Piece Quality Control Methods

Here are the main methods for assessing first piece quality:

1) Visual Inspection

Visual inspection can detect defects such as incorrect component positioning and poor solder joint

shapes.

2) Testing Instruments

Testing instruments can be used to find defects in the product, such as incorrect component parameters

and inadequate solder joint strength.

Circuitcardassembly’s TFT350 first piece tester has been awarded many patents at the national level

and is always in the forefront of SMT testing.

3) X-Ray Inspection

Use X-ray equipment to inspect and detect internal defects, such as components installed incorrectly or

voids.

First Piece Quality Control Process

Circuitcardassembly has implemented a strict process of quality control in the first-piece inspection.We

follow the following process:

1. Ask about the order by opening the MES and entering the label order number.

2. Please check the original documents as well as the production notes.

3. Double-click on the machine model in the BOM to access the engineering data.

4. Copy the BOM coordinates and the BOM from the SMT placement program.

5. Enter the test, launch the program, load your desktop image, and enter the furnace temperature to be

tested.

6. Check the material polarity on the drawings after testing capacitance and resistence.

7. After completing the test, select the result and click Finish Test.

8. Notify the production of the test results and pass the first piece through the furnace.

9. Check the product after passing through the furnace to see if it has passed through, the effect of

the furnace on the product, the tinning or deviation, the melting of the tin, etc.

10. Hang the first identification card, and then send it to sample production.

Quality of the First Piece

You should consider the following factors when conducting first piece quality assurance:

The first piece quality control should performed by experienced personnel.

The first piece should be checked for quality strictly according to the standards.

The first piece quality assurance should be able to detect and eliminate any defects as soon as

possible.

First Piece Quality Control: What Is It?

The first piece quality check is an important tool to ensure the quality of a product. It can prevent

the production and distribution of defective batch products.

The first piece can be thoroughly tested and inspected to detect and eliminate defects that may affect

the quality of the product. This will ensure that the product meets the customer’s requirements.

Conclusion

The key to product quality is SMT patching. Attracting attention is important.

We can prevent defective batches and guarantee product quality by strictly adhering to the standards of

first-piece quality assurance.