FCT Testing Equipment

FCT testing equipment is a significant tool to ensure PCBA quality.This article discusses the FCT test equipment's composition, types, and test indicators.

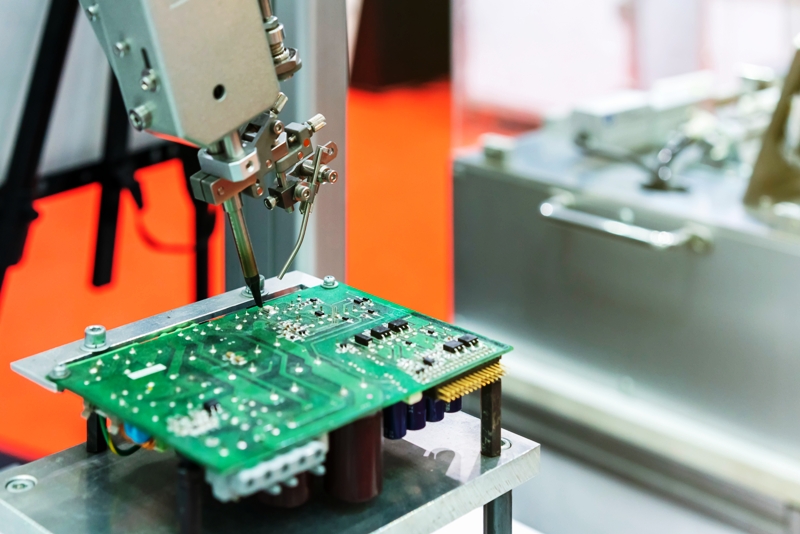

The PCB assembly FCT device is used

to determine if the assembled printed

circuit boards ( PCBA ) meet

the design requirements.

The FCT equipment simulates the actual use environment in order to test whether the PCBA performs its

functions correctly.

What Is FCT Testing Equipment?

The main components of FCT testing equipment are:

1) Test Machine

It is responsible for specific testing tasks. It includes the following components:

Controller: The controller controls the testing process and executes commands.

Test Probes: Test probes are connected to the test points on printed circuit boards

assemblies.

Test Software: is used to create test programs and analyse test results.

2) Test Fixture

Its main purpose is to secure the PCBA onto the testing machine. The FCT test fixture is made from metal

and features multiple holes for stabilizing the position of the PCBA.

The test fixture is designed to include the following features.

Reliability: The PCBA must be securely held by the test fixture to prevent it being

damaged or displaced during testing.

Accuracy: To ensure accuracy in the test results, the test fixture must be able locate

test points accurately on the PCBA.

Versatility: Test fixtures must be flexible enough to accommodate PCBAs in different

shapes and sizes.

3. Test the Software

Test software is responsible both for creating test programs and analysing test results. Its main

features include:

Generate a test program: Generate instructions sequences for the test machine.

Analyzing results: Analyze test results and create a report with information like test

results, time of the test, and status.

The following features are included in the test software:

Usability: Test software should have an intuitive interface that makes it easy for

operators to use.

Functionality: Test software must be able generate test programs which meet various

test requirements.

Compatibility: The software used to test the test machine must be compatible.

FCT Detection Indicators

FCT detection indicators include:

Speed of test: The speed of test refers to how long it takes the machine to perform a

test. The more PCBAs that can be tested, the faster the test speed.

Test Accuracy: Testing accuracy is the ability of the tester to detect faults or

defects. The more defects that can be detected, the higher the accuracy of the test.

Test Flexibility: Testing flexibility is the ability to test PCBAs of different types.

The greater the flexibility of testing, the more requirements can be met.

What Are the Different Categories of FCT Testing Equipment?

The FCT testing equipment is classified into three types based on the requirements for the tests.

1. Manual FCT equipment: Operated manually by the operator and suitable for small

batches.

2. Automated FCT equipment: Suitable for high volume production, this equipment is

operated automatically by machines.

3. Online FCT equipment: Perform the test while the PCBA is being manufactured,

suitable for online quality assurance.

4. Equipment for offline FCT: This equipment is ideal for batch testing after PCBA

manufacture.

Summary

The FCT equipment is an important tool for ensuring PCBA quality. FCT testing can help find PCBA faults

and defects, improving PCBA quality.

To ensure that the product meets customer requirements, it is important to meet the design

specifications and the performance of the end product.

related Posts

Contact us

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Skype: ali_youte

Email: sales@yt-electronic.com