Dual Inline Package (DIP)

This article introduces what is dual inline package(DIP) and what dip is used for and the workflow and technical application of DIP welding.

What Is a Dual Inline Package?

DIP is the abbreviation for dual inline package. It is a packaging form for integrated Circuits. ICs are

usually rectangular with parallel pins both on the left and right. Dual line packages can be soldered

directly to the PCB, or inserted into DIP

sockets. Dual in-line packages are widely used in car entertainment systems, controllers, switches, and

ICs.

Ceramic DIP and Plastic DIP are both available in dual-in-line packages.

What Does DIP Soldering Mean?

DIP soldering is also known as Dual In-Line Package Soldering. It’s a precision

connection technique in electronics manufacturing.

The PCB connects components with printed-circuit boards (PCBs), ensuring that they are reliable. PCBA

manufacturers perform the soldering in their PCBA factories. If you are looking to purchase a PCB

assembly or manufacturing, it is important to choose a reputable PCB manufacturer.

We are a PCB supplier and manufacturer. Our factories process PCBs and we offer a complete PCB assembly

solution. We can do everything about the PCB.

Dual In-Line Package Soldering Workflow

1) PCB Preparation

You prepare a PCB by drilling a series small holes into which you will insert the pins for the

electronic components. These holes can be sized and positioned according to the requirements of the

circuit to be designed.

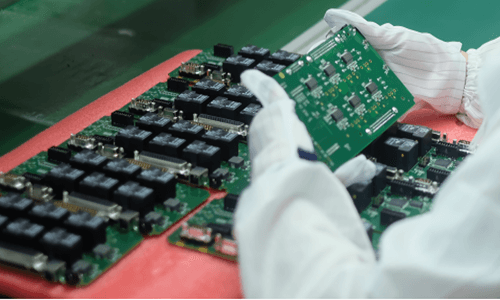

2) Component Installation

The pins are then inserted by a PCB assembly machine or assembler into the holes on the PCB. To ensure

that the components are aligned correctly and inserted, this step requires high precision.

3) Welding

Soldering is the next stage after the components have been inserted onto the PCB. DIP soldering is done

with tin, or a tin-lead mixture. These solders are melted at a certain temperature, and then applied to

the pins and pads of electronic components.

4) Solidification and Cooling

The solder will cool down and solidify after soldering. This will firmly connect the electronic

components with the PCB. This ensures that the connection is strong and stable.

5) Inspections and Tests

The finished circuit boards are then subjected for quality testing and functional testing, to ensure

that the solder connections are reliable and of high quality. These tests include electrical testing,

temperature testing, visual inspection and other types of testing.

DIP Welding Technology Application

DIP technology is used widely in many areas, including:

Consumer electronics: The DIP soldering process is crucial in the manufacture of

consumer electronic products such as mobile phones, tablets, TVs and audio equipment.

Industry Automation: The industrial automation equipment needs many electronic

components and sensors, and DIP-welding ensures reliability.

Medical Equipment: medical equipment is subject to very strict requirements in terms of

accuracy and reliability. DIP welding plays a major role in medical equipment, such as diagnostic and

monitoring instruments.

Communications equipment: Telephones, mobile base stations and communication network

equipment requires DIP soldering for the connection of various packaged electronic components.

Automotive Electronics: Modern cars have a large number of electronic sensors and

control units. DIP welding is used to ensure their connection and improve the performance and safety.

Future Trends

Future DIP soldering technologies may evolve in the following directions.

Development in surface mount technology: Surface mounted technology (SMT), which has

been adopted by many, may replace DIP soldering for higher component density.

Smart Manufacturing and Automation: Automation will be used to improve the production

efficiency of DIP soldering.

Environmentally friendly solder: An increased awareness of environmental issues will

encourage the development of environmentally friendly solder.

Improvements in high-density technology: In order to adapt to the miniaturized

electronic components, PCB design and DIP soldering technologies may continue to be improved to meet

high-density technology.

Circuit board manufacturing: The 3D-printing technology can be used to provide greater

design flexibility.

Summary

DIP soldering, in conclusion, is an important technology for electronic manufacturing. It provides

reliable connections to various electronic devices.

DIP soldering will continue to evolve to meet the changing needs of the market and to enhance

performance and reliability.