Flexible PCB (FPC): The New Trend in Electronic Design

This article introduces the advantages, classification, and production process of flexible PCB,and their differences from traditional PCB.

Abstract: Due to the constant upgrading of products and the need for PCBs, flexible circuit boards were

introduced. Their market demand has been growing. FPCs are used in medical, aerospace, and consumer

electronics.

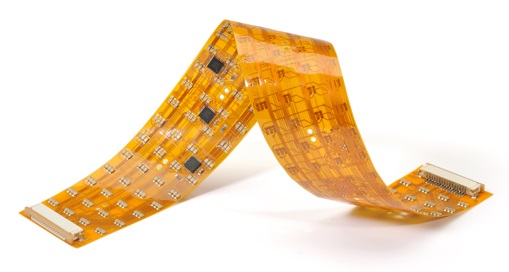

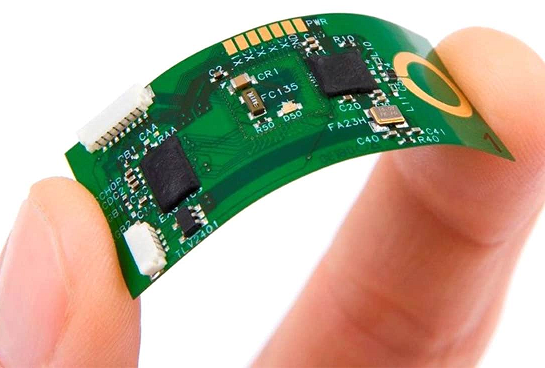

Flexible PCBs are circuit boards with magical

properties. They can fold, bend, wrap and move around in a small space, like a snake. How does it

achieve this? This article will answer your question.

What Is FPC

Soft boards are also known as flexible circuit boards. Many insulating materials are available for

flexible assemblies, including polyimide(PI), polyester film(PET), aramid fibre paper (Nomex), or

polyvinylchloride (PVC).

The circuit board can be made flexible by embedding the circuit design onto plastic sheets. This allows

for more electronic component to be placed in order.

Flexible PCBs are a breakthrough in interconnection technology. It is popular due to its light weight,

high flexibility and thin thickness. It is simple to install.

In the United States, flexible printed circuits were developed in the 1970s for space rocket technology.

Its excellent properties make it useful in many different fields.

FPC Advantages

1) High Flexibility

The circuit board can be folded and bent without damaging it. It can be laid out in any layout,

stretched and moved in a limited space. It’s ideal for SMT assembly.

2) Thin and Lightweight

The circuit board layout is compacted, which reduces the size of the product, the weight and makes it

easier to transport. It promotes high-density electronic products, as well as high reliability and

miniaturization.

Flexible circuit boards are best suited for products that need to take into account the space issue.

3) Improve Design Flexibility

There are many circuit board designs due to the lightweight, thinness, and flexibility of PCBs. This

increases the PCB’s reliability and performance.

has many advantages, including good heat dissipation, solderability and ease of installation.

Flexible Printed Circuit Board Classification

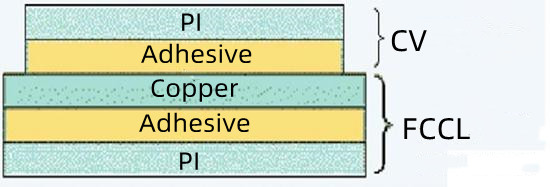

1) Single-Sided Flexible Board

Use a single-sided, flexible copper-clad PI board. Cover the circuit with a protective sheet after it is

completed to create a circuit board for a single conductor. The cost is the lowest.

Single-sided flexible boards are recommended when the electrical performance requirements or

single-sided wiring is not high.

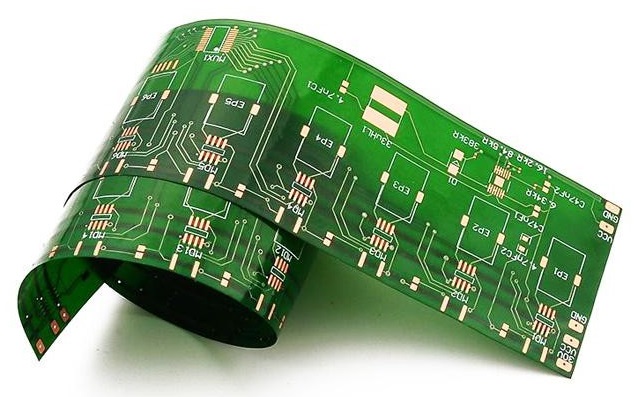

2) Double-Sided Flexible Board

Double-sided flexible copper-clad laminate is best. A protective film is applied on both sides after the

circuit has been completed to create a dual-conductor board.

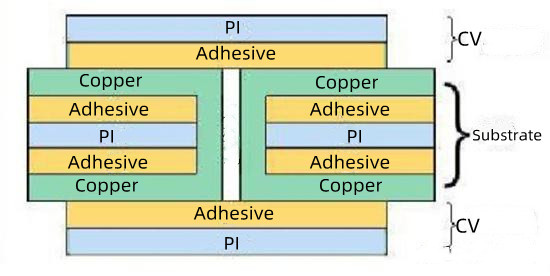

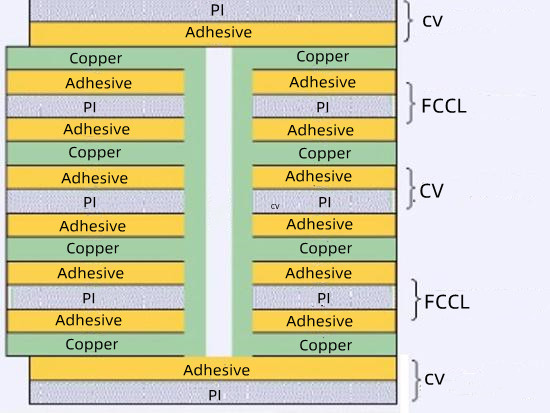

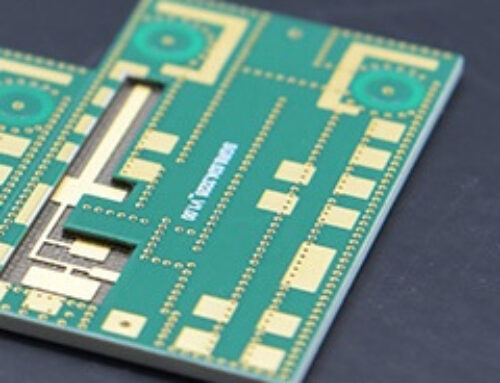

3) Multilayer Flexible Board

Multilayer Flexible Boards are made by stacking three or more circuit boards. Through drilling and

electroplating, they form metalized holes to create conductive paths.

When designing PCB layouts, it is important to consider the component assembly and manufacturing of the

PCB.

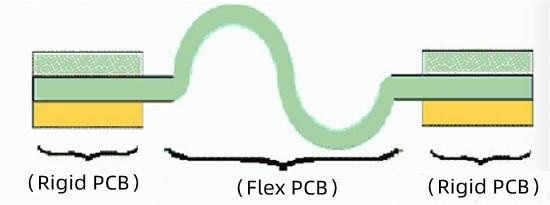

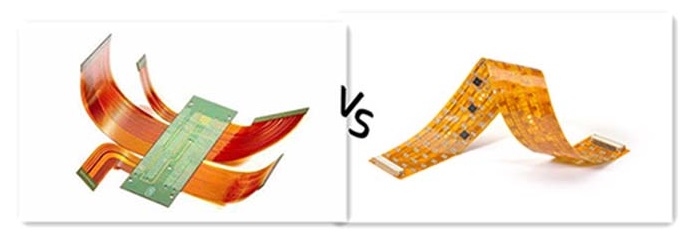

4) Rigid-Flex PCB

Rigid Flex PCB consists of rigid PCBs and flexible PCBs that are selectively stacked. It combines the

benefits of rigid and flexible circuit boards (bendability, sturdy rigidity).

The price of this PCB is higher. Therefore, when you manufacture it, you may want to consider reducing

the layers.

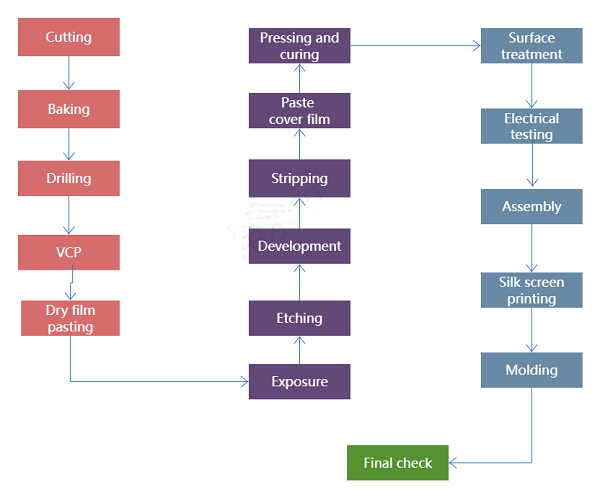

Flexible PCB Manufacturing Process

Double-layer board production is shown here. Single-layer boards don’t require holes for drilling or

metallization.

Cutting: Cut material to required size according the size of the order. Primary

equipment includes an automatic cutting machine as well as a manual machine.

Baking: Dry out the moisture in the substrate so as to avoid shrinkage and

stratification. The oven is used, with the parameters of 120degC over 2 hours.

Drilling: The drilling of holes and vias in the substrate. This prepares the substrate

for subsequent processes, such as hole metallization. The CNC drilling machine is the primary device.

Black Hole: In this step, through the black hole, a layer conductive carbon powder will

be directly deposited onto the hole wall, PI. This replaces the traditional copper deposition. This step

prepares the copper plating. It is the black-hole line.

VCP: It is vertical conveyor plating that uses copper electroplating in order to

thicken both the wall of the hole and the surface copper, according to customer request.

Pre-treatment for dry film: Remove oxidation from the surface of the board using

chemical cleaning.

Dry Film Pasting: The copper foil is coated with a layer of dry photosensitive film.

This step is completed in a dust free workshop with an automatic film pasting machine.

Exposure: The image of the circuit-pattern film is transferred onto the dry film

according to the film exposure that corresponds to the order. The device is an automatic exposure

machine.

Development: Dissolve the dry film that has not been exposed in a sodium carbonate

solution. This will form a pattern of a film.

Etching: Copper foil that is not covered by the dry film, is etched to form a circuit.

Stripping: Remove any exposed film that is dry on the circuit protector. The horizontal

DES line is used for developing, etching and stripping.

Pretreatment of covering films: The effect and method of pretreatment are the same as

for dry film.

Apply the cover films: align the cover films with the marking lines. Then, apply the

cover films to the board using high heat.

The cover film is used to protect and insulate the circuit. Equipment includes an automatic laminating

machine for cover films, irons, etc.

Curing: The glue between the film covering and the board can be cured by

high-temperature pressing, high-pressure pressing, and baking at high temperatures. Primary equipment

includes a press machine and an oven.

Surface Treatment: Flexible printed-circuit surface treatment includes immersion gold

or plating.

Metals like nickel or gold can be deposited using electroplating or chemical methods on the FPC pads

exposed according to the customer’s requirements. It protects and maintains the solderability of the

pads.

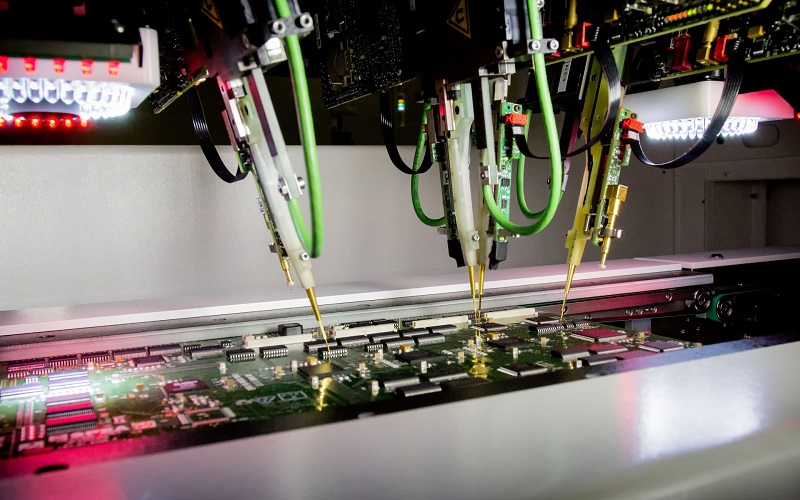

Electrical Testing: Check for open short circuits and four-wire defects using

mechanical equipment. Electrical testing machines and flying probe testers are the primary devices.

Assembly: The electromagnetic film or reinforcement is attached according to the hole

positions or alignment marks. Equipment includes soldering irons and irons as well as automatic

reinforcement machines.

Silkscreen printing: Printing ink on products using the screen-printing principle. This

is mainly used to print product models, production cycle logos and various component logos.

The main equipment includes a text inkjet, oven and silk screen printer.

Moulding: After mechanical or laser cutting, the final product shape is determined by

the customer. Laser-cutting equipment is used.

Final Check: Visually inspect the product and its surface to determine if it is in good

condition or not.

Test the reliability of the product and confirm that it meets your customer’s requirements.

Equipment includes CCD, AVI and reliability testing equipment.

We can see from the introduction of each production process that FPC requires different technologies.

The production process can be difficult and time-consuming. Flexible circuit boards are more expensive

to manufacture than PCB.

It takes longer. FPC is a flexible, lightweight, and reliable material that offers many possibilities in

equipment and products. It is also increasingly popular among engineers.

Rigid PCB vs Flexible PCB

1) Base Material

Different substrates are used by rigid and flexible circuit boards. Flexible circuit boards are made of

polyester film and polyimide, while rigid circuit boards are made from glass fiber.

2) Plasticity and flexibility

Flexible Circuit Boards are flexible, can be bent and folded at will and have a strong plasticity. Rigid

circuit board cannot be bent. They are used to organize and stabilize electronic components.

3) Applicable Scenarios

Flexible printed circuit boards are primarily used for flexible circuits such as flexible displays and

automotive panels. They can also be used to make other products which need to fold, bend, or reduce in

size.

PCB can be used for circuit boards with various specifications such as audio circuit boards and signal

circuit boards.

4) Features

Flexible PCB Advantages: Lightweight, small size; can be used with less space. High

reliability. Can withstand greater bending and folding.

High cost and complicated manufacturing process are the main disadvantages. Strong plasticity, easy

static accumulation, and proneness to short circuits, failures, and short circuits, are also problems.

The advantages of PCB: PCB assembly can be simple and stable. Low manufacturing costs.

Automation can increase production efficiency.

There are several disadvantages to this design, including its size, weight, inability to resist falling

and the limited space.

Summary: Different types of circuit board have advantages and disadvantages. We choose

the circuit board based on product requirements, costs, performance and environmental protection. The

PCB manufacturer then produces it.

Flexible Circuit Boards

Due to its outstanding characteristics, flexible printed circuit boards are widely used in many

different fields. Specific applications include:

1) Consumer Electronics

Flexible circuit boards are used in consumer electronics such as smartphones, notebooks, etc. As an

example, flexible circuit boards can be used to achieve a highly integrated design. This makes the phone

thinner, beautiful and more reliable.

2) Medical Field

To improve comfort and portability, flexible circuit boards can be used to connect wearable devices,

medical equipment, and other products.

3) Car

Flexible circuit boards are used in the automotive industry to cope with the complex circuit layouts,

vibrations, and environments. This improves the safety and reliability.

4) Aerospace

Flexible circuit boards are a popular choice in aerospace due to their light weight and high

reliability.

What should you consider when choosing a flexible PCB manufacturer?

You should ask these questions before selecting a manufacturer of flex circuits:

• Can the manufacturer meet the specifications for your flexible circuit boards?

• Is flexible Pcb manufacturer professional proofing or small batch?

• Do you have any specific requirements for the quality of flexible printed circuits?

• Does the FPC budget match your manufacturer’s quote?

• How quickly can FPC manufacturers deliver products?

Yt-electronic is a PCB assembly company that has been in business for over 12 years.

Our PCB assembly service is a one-stop shop. Yt-electronic can handle everything, from PCB assembly to

component procurement.

We have a highly-qualified technical team, as well as multiple PCB manufacturers and PCB suppliers. Contact us if you require any PCB service.