High-Volume PCB Assembly

This article introduces the applications and advantages of high-volume PCB assembly, and the advantages of yt-electronic's high-volume PCB assembly service.

Factors such as the size of the company and stage of a project can affect different customers. PCB Assembly also varies in

quantity. PCBA manufacturers that can handle large-scale assemblies are the best choice for customers

with a high PCB demand. Not all PCBA factories are capable of mass production. High-volume PCB Assembly is

dependent on the size of the company and the level of automation.

By choosing a reliable manufacturer, you can reduce the risk of switching manufacturers in the middle of

a high-volume PCB production process. Yt-electronic offers high volume PCB assembly. You can select

consigned or turnkey assembly depending on your requirements. We will meet your needs for high-quality

assembly, no matter what type of assembly you choose.

High-Volume Assembly PCB Definition

The term high-volume PCB assembly is used to describe projects that have more than 10,000 printed

electronic circuit boards. Electronics manufacturing companies are attracted to this process because of

its consistency, uniformity and automation.

Benefits of High-Volume PCB Assembly

1) One-Time PCB Design and Prototyping Process :

PCB design is a one-time process. PCB Assembly is interdependent and unified as it is a mass-production

process. This process is just as important as building a home. The next project can be affected if the

foundation is not stable.

2) Shortened Cycle Time for Production:

The entire production process can be automated, which reduces the investment in labor. Manual assembly

is usually labor-intensive and time-consuming. Fully automated equipment is used for 24 hour production.

3) Quality Consistency:

Multiple PCBs are made at the same moment, making it easier to maintain the quality of all parts. This

means that you won’t need to worry about a PCB being different than the rest and causing issues.

4) Reduce the Cost

Costs are reduced by purchasing automation equipment and assembly parts in bulk. The cost of design,

manufacture, and testing is reduced by mass production.

Yt-electronic High Volume PCB Assembly Capabilities

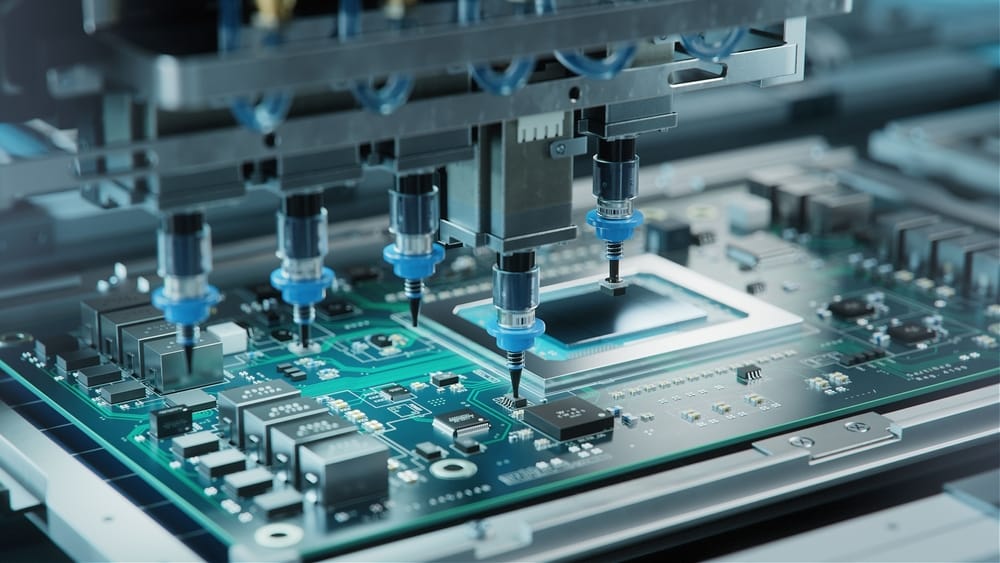

• Fully automated equipment production lines, 24-hour working

• SMT, PTH or a mix of both technologies

• Manual welding (and machine welding)

• Jet solder paste or screen solder past printing can reduce delivery times.

• Functional testing equipment that is comprehensive and efficient

• Lead-free or leaded assembly processes

Why Choose Yt-electronic for Your PCB?

1) Quality Assurance:

Our company is a leader in board assembly, and we have a full supply chain to purchase original

components.

2) Strict Quality Inspection:

We have the latest fully automated assembly machines and an experienced team that can meet your needs

and solve complex assembly issues. Inspection methods include X-ray, automatic optical inspection (AOI),

in-circuit test (ICT), functional test, etc.

3) Cost-Effective PCB Assembly Plan:

Our professional procurement team, along with our outstanding component suppliers allows us to maintain

a balance between cost and quality during PCB assembly. If you need high-quality and affordable PCB

assembly, then we can help.

4) High-Quality Services:

Our company is an independent manufacturer. The entire PCB assembly is done by our company. We are only

here to serve you. You only need to contact us, tell us what you want and we’ll make a plan for

everything from the procurement of materials to high-volume PCB assembly and production.

PCB Assembly for High Volume Applications

High-volume PCB assembly can be used in many different fields. The following are the main points:

1) Electronic Devices:

High-volume PCB assembly is used in many electronic devices such as smartphones and laptops to improve

functionality and efficiency.

2) Aerospace Industry:

As aircraft depend on electronic systems, it is crucial to produce PCBs in high volume.

3) Automotive Industry:

As PCBs are essential to many automotive systems and components, high-volume PCB assembly can be helpful

for the production of cars.

4) Medical Industry:

Medical devices that are used for surgery, treatment and diagnostics can be assembled in high-volume.