Specifications and Anomalies of SMT Processes

This article introduces SMT process specifications and common anomalies, including equipment specifications, material specifications, etc.

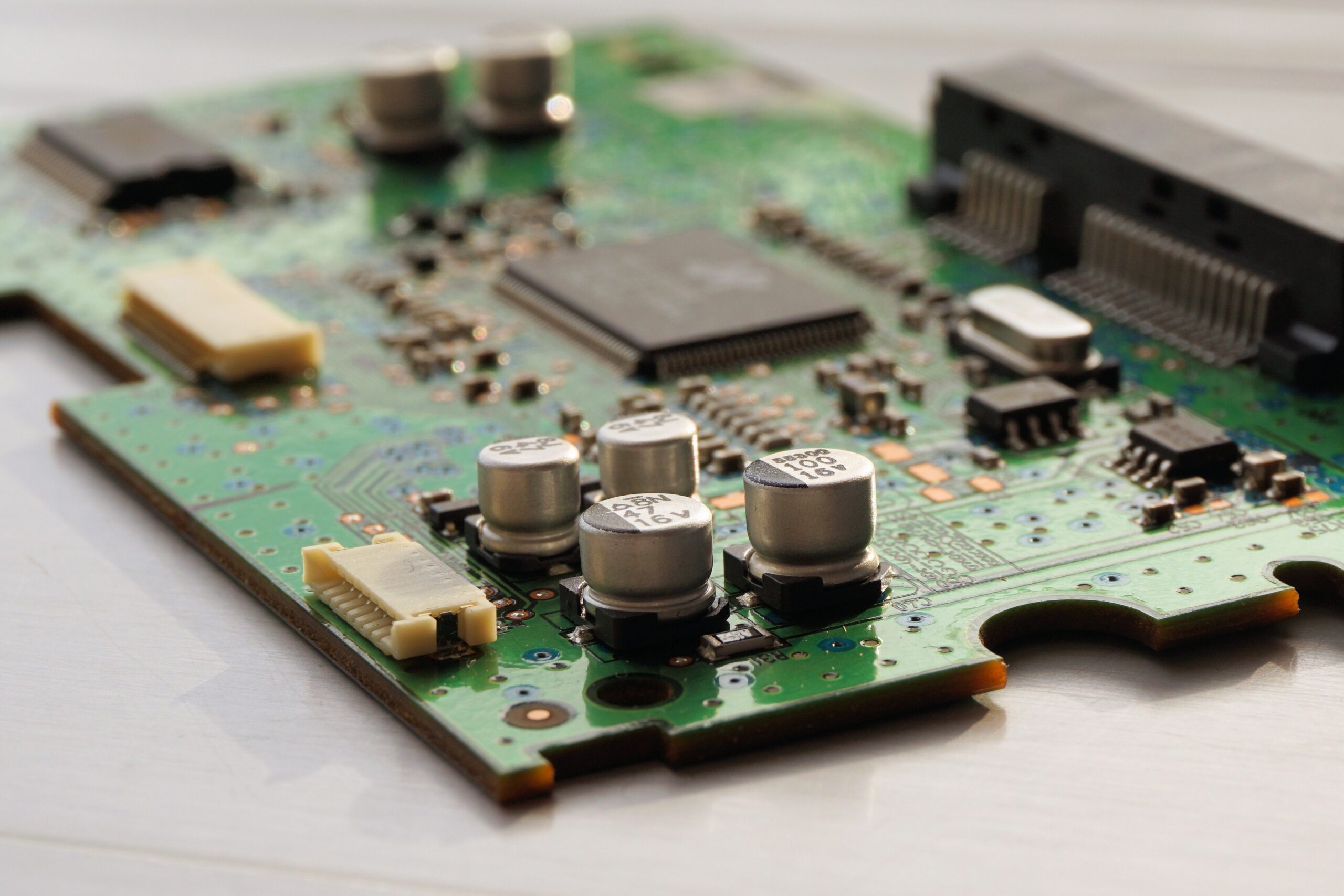

Surface mount technology is the SMT process specification. It is a standard requirement for PCB Assembly and is a crucial basis

to ensure product quality.

What Are the SMT Process Specifications?

1) Specifications of Equipment

Placement Machine: The model, specifications and performance must be met.

Reflow Oven: model, specifications and performance of the reflow oven, as well as its

usage methods.

Visual Inspection Equipment: Model, specifications, performance and usage methods of

the equipment must meet specifications.

Automated Testing Equipment: models must comply with the standard. Performance and

usage methods are also required to be in compliance.

2) Material Specifications

Solder paste: solder paste model, specifications, performance, usage methods, etc.

Components: component models, specifications, performance and usage methods must meet

standard

PCB: PCB model, specifications, performance, usage methods, etc.

3) Process Specifications

Solder paste printing process: steps, parameters, precautions, etc. Solder paste

printing.

Process: Steps, parameters, cautions, etc.

Reflow Process: reflow parameters, steps, and precautions.

4) Inspection Specifications

Visual inspection: methods, standards, frequency, etc. Visual inspection.

Automated Testing: methods and standards, frequency etc. Automated testing.

Common SMT Abnormalities

Anomalies in the SMT process, such as tombstones, solder beads and bridging can affect product quality.

1) Solder Beads

Solder beads is one of the most common anomalies that occurs in SMT.

The pad will appear to have small particles of solder. Solder beads are formed for a variety of reasons.

• The wrong selection of solder paste.

• The opening of the steel plate is not suitable.

• The pressure mounting is too much.

• The furnace temperature curve is incorrect.

2) Erection of a Monument

The rectangular component looks like a chip with one end soldered on the pad, and the other sticking

out.

• There are many reasons to erect a monument.

• Inconsistent thermal performance.

• Inconsistent solderability on PCB pads or components

• Mounting offset.

This will result in a poor appearance of the product and may even have an adverse effect on its

function.

We must therefore take steps to prevent tombstones from appearing.

3) Bridging

Solder is used to connect the solder joints, which causes a short-circuit. Bridging can be caused by:

• Opening the steel mesh is inappropriate.

• Too much soldering paste

• Solder paste collapse.

• The reflow speed is too slow

The contact force between the components and the solder paste must be reduced.

4) Incoming Material Rejection

The most common SMT anomaly is the material that comes in.

The solder is not forming a good bond with the component or the PCB pad. These are the main causes:

• Oxidation or corrosion of PCB pads and components.

• Surface defects on components or PCB pads.

• Problems with the manufacturing process of PCB pads or components

• Other anomalies, such as component lifting, component shifting, missing, etc., may also occur during

the SMT process.

The anomalies may also cause product quality problems and they should be detected and dealt with as soon

as possible.

Summary

Anomalies in the SMT process, such as tombstones, solder beads and bridging can affect product quality.

To prevent quality issues, SMT processes must be managed. Implement these specifications strictly,

improve the management of materials, equipment, and inspections to reduce the likelihood of product

quality issues. PCB producers should continue to develop new technologies for PCB assembly.