Rigid-Flex Printed Circuit Board (Rigid-Flex PCB)

This article focuses on the advantages and specific application scenarios of the rigid-flex printed circuit board compared to rigid and flexible circuit boards.

What Is A Rigid-Flex Printed Circuit Board?

A rigid-flex PCB is a printed circuit board which combines a rigid

board with a flexible circuit board. Flexible

circuit boards are flexible and bendable, while rigid circuit boards offer good stiffness and

strength. The Rigid-Flex Printed Circuit Board has the advantages of both rigid PCBs

and flexible FCBs.

Advantages of Rigid-Flex Printed Circuit Boards

• Board size and system weight can both be reduced by eliminating the need for cables and

connectors between rigid components.

• By maximising space to reduce the number of components

• The use of fewer solder joints increases the reliability of connections.

• The assembly of rigid-flex printed circuit boards is easier than that of flexible boards.

• Simplify assembly process.

• Using rigid-flex printed circuit boards can reduce logistics and assembly costs.

• The complexity of the mechanical design can be increased, which will also increase the

optimization of the shell solution scheme.

Flexible PCBs Are Used in a Variety of Applications

The following are the main areas where rigid-flex printed circuit board are used:

• Adapts to Complex Shapes

Flexible rigid PCBs can be cut or bent according to our needs. Wearable Products, medical equipment and

wearable products are all examples of small-space applications that can benefit from this type of PCB.

• Integrate Your Business Better

The rigid-flex PCB allows multiple components to be integrated onto one board, improving the system

integration and reliability.

• Reduce Costs

The rigid-flex printed circuit board can reduce the amount of circuit boards and thereby reduce

manufacturing costs. This is useful as a consumer electronic product.

Applications of Rigid-Flex PCB

Many industries use rigid-flex printed circuit board, including:

• Medical Field

Medical applications of rigid-flex printed board technology are not only limited to sensors, monitoring

equipment and surgical instruments. They also include wearable equipment, medical imaging and medical

instruments. The compact rigid-flex PCB design, as well as its biocompatibility, make it an important

component of modern technology.

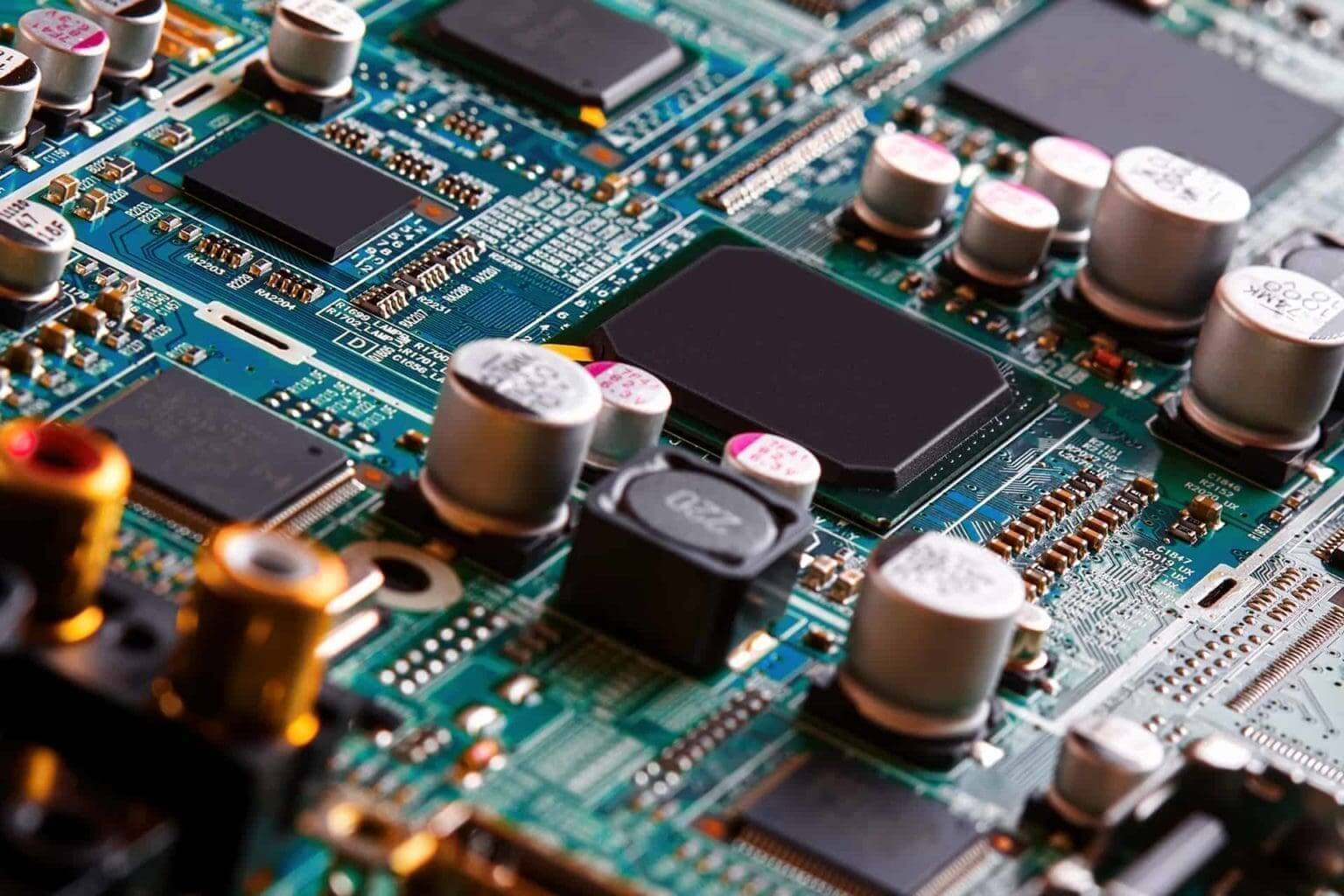

• Consumer Electronics

These rigid-flex PCBs are widely used in consumer electronic products such as mobile phones, tablets,

televisions and digital cameras. They achieve compact designs, high performance and reliability. These

rigid-flex PCBs are used to support a variety of convenient technologies.

future Development

As electronic products turn to smaller, lighter, and more flexible aspects of development.In the

future,rigid-flexible circuit boards will be more widely used.

The future of rigid-flex PCBs will be characterized by the following:

• Higher Reliability

Rigid-flex circuit boards will use more advanced materials and processes to improvetheirreliability.

• Lower Cost

As the manufacturing costs of rigid-flex boards decrease, they will become more popular.

• Wider Application

In new applications such as flexible sensors and electronic devices, rigid-flex printed circuit board

will be developed.

Summary

The rigid-flex printed circuit board has

unique advantages that make it widely used in many important areas.

With the continuous development of technology,rigid-flex PCB will be more widely usedin the futureand

willhave a profound impact on the design and manufacturing of electronic products.