Multi-Layer PCB Vers Single Layer PCB

This article delves into the advantages of multi-layer PCBs and single-layer PCBs, as well as some key improvements provided by multi-layer PCBs.

Table of Content

We'll compare the advantages of multi-layer versus single layer PCBs. Multi-layer PCBs offer a number of

critical benefits, including:

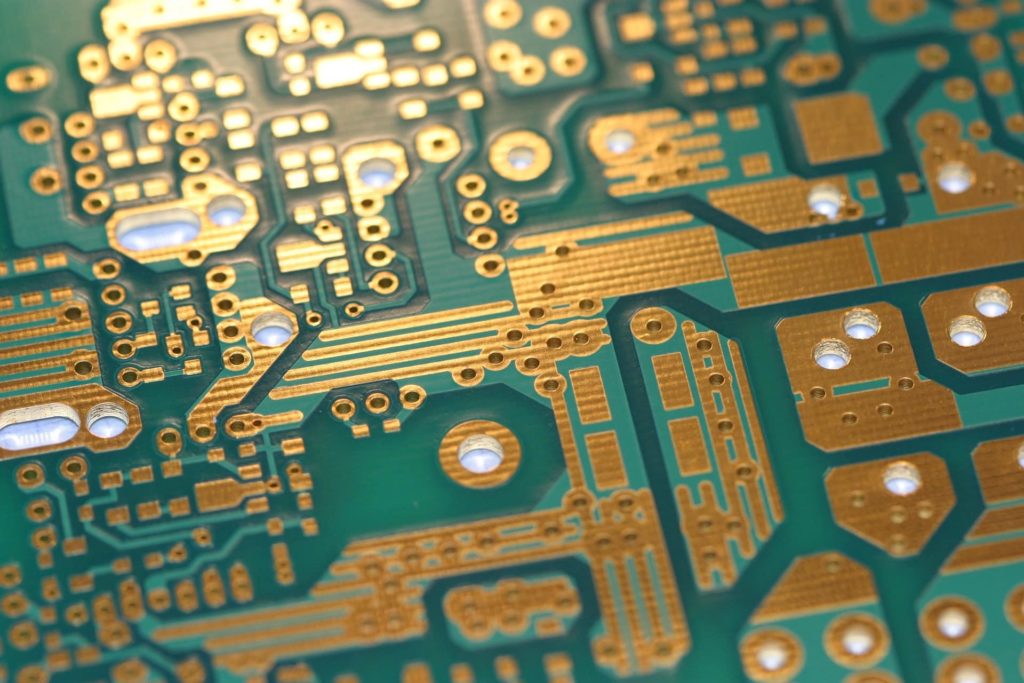

High Assembly Density

The density of multilayer PCBs can be increased by layering. The increased density allows greater

functionality, speed, and capacity despite the smaller PCB.

Smaller Size

Multi-layer PCBs have a smaller overall size than single-layer ones. Multi-layer PCBs can increase the

surface of the circuit without increasing its size. Single-layer boards must increase their surface by

increasing their size. Multi-layer PCBs can be used in smaller products, but larger single-layer boards

must be installed on larger devices.

Lighter Weight

Multilayer boards can reduce the number of connectors, and therefore weight. This is a great solution

for electrical applications that require complex wiring. Multi-layer boards can do the same work as

multiple single layer PCBs but in a smaller format and with fewer connecting parts, reducing weight. It

is important to consider this when designing electronic products that are lighter.

Multi-layer PCBs offer more design capabilities than single-layer ones. Multi-layer PCBs are able to

achieve more despite their small size and light weight, by incorporating greater controlled impedance

capability, greater EMI shielding and improved overall design quality.

Yt-electronic: So, what are these factors when deciding whether to use multi-layer or

single-layer structures. If you're producing a complex, small device that is lightweight and

requires high quality, then a multilayer PCB could be the best option. If weight and size are not

important factors for your product, then a double-layer or single-layer PCB may be a more cost-effective

design.

related Posts

Contact us

WhatsApp: +86-13570802455

Wechat: +86-13570802455

Teams: alek_youte

Email: sales@yt-electronic.com