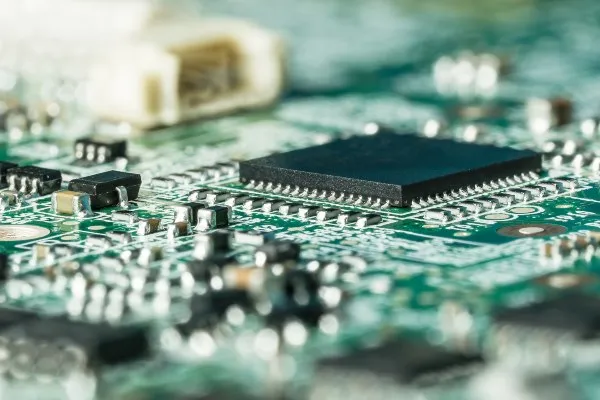

How Do You Perform Manual SMD Welding (SOIC)?

This article introduced how to use SMD IC Welding Techniques connect the SOIC integrated circuit (make sure it is aligned correctly) to a corner pad.

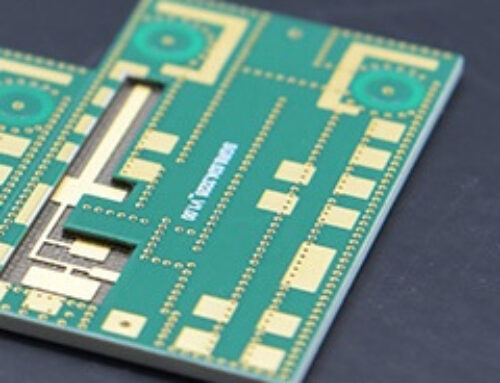

SMD IC Welding Techniques

1. Prepare a rectangular tip of welding iron and ensure it is clean.

2. A welding station must be equipped to control the welding temperature.

3. Connect the SOIC integrated chip (ensure it’s aligned correctly!) to a corner pad.

Apply welding on the other side of two or three pins.

The trick is to not connect all the pins together at once.

The board can now be tilted at 45 degrees or 60 degrees to allow gravity to flow downward and the

welding joints.

4. Use the welding tip and “pull” down the welding joints.

This method works on the principle that the tension between welding molecules and the pad is greater

than between the two.

so the welding group will break from the “upper” pin.

You can achieve consistently high-quality results when welding all pins.

You can save some seconds.

Hand welding does not look professional.

All connection points must be consistent and equal during welding.

It is nearly impossible to weld gaskets by hand, and it usually takes a few minutes. It can be done

quickly. (I haven’t used a TSSOP on a factory PCB, like a professional circuit. But I’m satisfied with

SOIC for the time being).

Currently, you can easily use SMD ICs without any special equipment, and their use is simpler than

traditional ICs. You need to stop thinking that “if I intentionally connect the IC’s pins using

welding, this could cause damage.”

You don’t need to use dewelding metal wires in most cases.

Furthermore, a major advantage of SMD ICs is their ability to be removed easily from PCBs when needed,

while DIL ICs are almost impossible to remove without causing any damage.